Dab tsi yogflux-cored arc vuam?

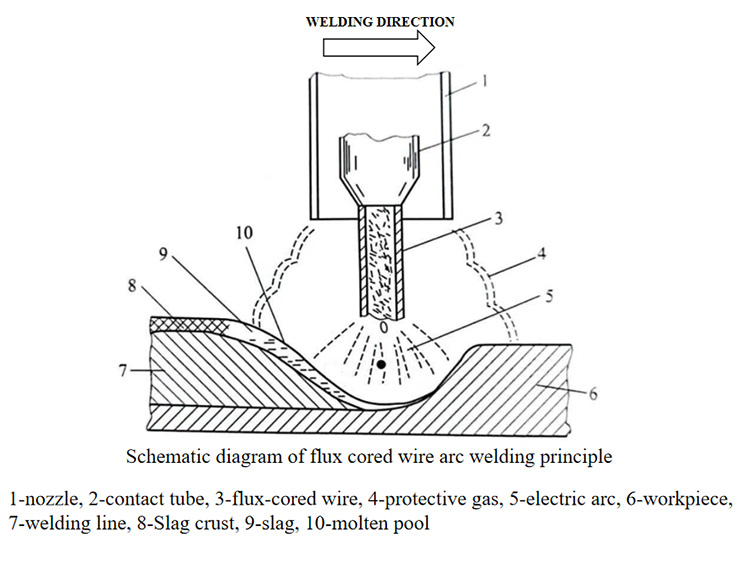

Flux-cored hlau arc vuam yog ib txoj kev vuam uas siv cov arc ntawm flux-cored hlau thiab workpiece kom sov, thiab nws lub npe lus Askiv tsuas yog FCAW.Nyob rau hauv qhov kev txiav txim ntawm arc tshav kub, vuam hlau hlau thiab workpiece yog txuas nrog melting, tsim ib tug weld pas dej ua ke, arc rau pem hauv ntej tom qab lub crystallization ntawm lub weld pas dej ua ke.

Dab tsi yog flux-cored hlau?Cov yam ntxwv ntawm cov cartridge yog dab tsi?

Flux-cored welding hlau yog ib hom vuam hlau ua los ntawm dov nyias steel sawb rau hauv cov yeeb nkab steel los yog cov yeeb nkab tshwj xeeb zoo li steel, sau cov yeeb nkab nrog qee yam ntawm cov hmoov, thiab kos duab.Cov txheej txheem ntawm cov hmoov txheej yog zoo ib yam li cov electrode txheej, uas yog tsim los ntawm arc stabilizing tus neeg saib xyuas, slag forming tus neeg saib xyuas, gas forming agent, alloying agent, deoxidizing agent, thiab lwm yam.

Dab tsi yog lub luag haujlwm ntawm flux nyob rau hauv flux-cored hlau?

Lub luag hauj lwm ntawm cov flux yog zoo ib yam li cov electrode txheej, thiab muaj ntau yam hauv qab no.

① Tiv thaiv cov nyhuv ntawm qee cov khoom hauv vuam flux decomposition, qee qhov melting!Lub decomposition ntawm vuam flux tso pa roj, uas muab ib co los yog feem ntau tiv thaiv.Lub molten flux tsim ib lub molten slag, uas npog lub nto ntawm lub tee dej thiab lub pas dej molten, thiab cov kua hlau tiv thaiv nws.

② Arc stabilizer nyob rau hauv arc stabilizer cartridge tuaj yeem stabilize arc thiab txo tus nqi spatter.

③ Alloying action Ib txhia ntawm cov ntsiab lus alloy hauv cov tub ntxhais tuaj yeem ua cov vuam vuam.

④ Deoxidation alloy cov ntsiab lus ntawm slag tuaj yeem hnov mob nrog kua hlau.Txhim kho qhov muaj pes tsawg leeg ntawm weld hlau, txhim kho nws cov khoom siv kho tshuab.

Tsis tas li ntawd, cov slag npog tseem tuaj yeem txo qhov cua txias ntawm lub pas dej molten, ua kom lub sijhawm muaj sia nyob ntawm lub pas dej molten, uas yog qhov zoo los txo cov ntsiab lus ntawm cov pa phem hauv qhov vuam thiab tiv thaiv porosity.

Dab tsi ntawm flux cored arc vuam muaj?

Muaj ob hom flux cored hlau arc vuam (FCAW-G) thiab kev tiv thaiv tus kheej (FCAW-S), nyob ntawm seb puas siv cov roj thaiv sab nraud los yog tsis siv.

Cov roj shielded vuam ntawm flux-cored hlau feem ntau yog siv cov pa roj carbon dioxide lossis carbon dioxide ntxiv rau argon ua cov roj tiv thaiv, thiab cov flux hauv cov hlau muaj me ntsis gassing agent.Txoj kev no zoo ib yam li cov pa roj shielded vuam.Kev tiv thaiv tus kheej welding tsis xav tau cov roj tiv thaiv sab nraud.Muaj ntau tus gasifier hauv flux, thiab cov pa roj thiab slag decomposed los ntawm gasifier yog siv los tiv thaiv.

Dab tsi yog qhov zoo ntawm flux-cored arc vuam?

Flux-cored arc vuam muaj qhov zoo hauv qab no.

(1) Cov khoom siv vuam zoo siab melting efficiency (txog 85% ~ 90%), ceev melting ceev;Rau cov vuam tiaj tiaj, txheej txheej ceev yog 1.5 npaug ntawm phau ntawv arc vuam, thiab rau lwm txoj haujlwm vuam, nws yog 3-5 npaug ntawm phau ntawv arc vuam.

② Cov txaws me me, weld tsim cov tshuaj zoo core ntxiv arc stabilizer, yog li arc stability, me me txaws, zoo weld tsim.Vim hais tias lub pas dej molten yog them nrog molten slag, weld nto zoo zoo dua li ntawm cov pa roj carbon dioxide vuam.

(3) Kev siv vuam zoo Vim tias cov roj slag ua ke tiv thaiv, nws tuaj yeem tiv thaiv cov pa phem los ntawm kev nkag mus rau qhov chaw vuam.Tsis tas li ntawd, lub sijhawm muaj nyob ntawm lub pas dej molten yog ntev, uas yog qhov zoo rau cov nag lossis daus, yog li cov vuam muaj cov ntsiab lus tsis tshua muaj hydrogen thiab cov porosity zoo.

(4) Muaj zog adaptability tsuas yog yuav tsum tau kho qhov muaj pes tsawg leeg ntawm solder hlau cored, nws muaj peev xwm ua tau raws li qhov yuav tsum tau ntawm cov hlau sib txawv ntawm cov weld muaj pes tsawg leeg.

Dab tsi yog qhov tsis zoo ntawm flux-cored arc vuam?

Lub shortcomings ntawm flux-cored arc vuam yog raws li nram no.

Piv nrog roj shielded vuam, tus nqi ntawm vuam hlau yog siab dua thiab cov txheej txheem tsim khoom yog complex.

② Hlau pub mis yog qhov nyuaj, nws yog ib qho tsim nyog yuav tsum siv lub tshuab pub hlau uas nws clamping siab tuaj yeem hloov kho kom raug.

③ Lub cartridge yog ib qho yooj yim los nqus dej noo, yog li nws yog ib qho tsim nyog yuav tsum ua kom cov vuam hlau nruj me ntsis.

④ Slag tshem tawm yog xav tau tom qab vuam.

⑤ Ntau cov pa luam yeeb thiab cov pa phem raug tsim tawm hauv cov txheej txheem vuam, yog li qhov cua yuav tsum muaj zog.

Dab tsi tiv thaiv roj feem ntau yog siv hauv flux-cored arc vuam?Cov yam ntxwv ntawm txhua tus yog dab tsi?

Flux cored hlau arc vuam feem ntau yog siv cov pa roj carbon dioxide ntshiab lossis cov pa roj carbon dioxide thiab cov roj argon ua cov roj tiv thaiv.Cov roj hom yuav tsum tau xaiv raws li cov flux-cored hlau siv.

Argon yog yooj yim ionized, yog li nws yog ib qho yooj yim mus cuag ejection hloov nyob rau hauv argon arc.Thaum cov ntsiab lus argon ntawm cov roj sib tov tsis pub tsawg dua 75%, qhov flux cored hlau arc vuam tuaj yeem ua tiav kev hloov pauv dav hlau ruaj khov.Nrog rau qhov txo qis ntawm cov ntsiab lus argon, qhov nkag mus tob zuj zus, tab sis qhov arc stability txo qis thiab tus nqi spatter nce.Yog li, qhov zoo tshaj plaws roj sib tov yog 75% Ar + 25% CO2.Tsis tas li ntawd, Ar + 2% O2 kuj tuaj yeem siv rau kev sib xyaw roj.

Thaum cov pa ntshiab CO2 raug xaiv, nws yuav decompose nyob rau hauv qhov kev txiav txim ntawm arc tshav kub thiab tsim ib tug loj tus naj npawb ntawm cov pa atoms, uas yuav oxidize manganese, silicon thiab lwm yam ntsiab nyob rau hauv lub molten pas dej ua ke, ua rau cov hlawv ntawm alloying ntsiab.Yog li ntawd, welding hlau nrog siab manganese thiab silicon ntsiab lus yuav tsum tau siv.

Post lub sij hawm: May-09-2023