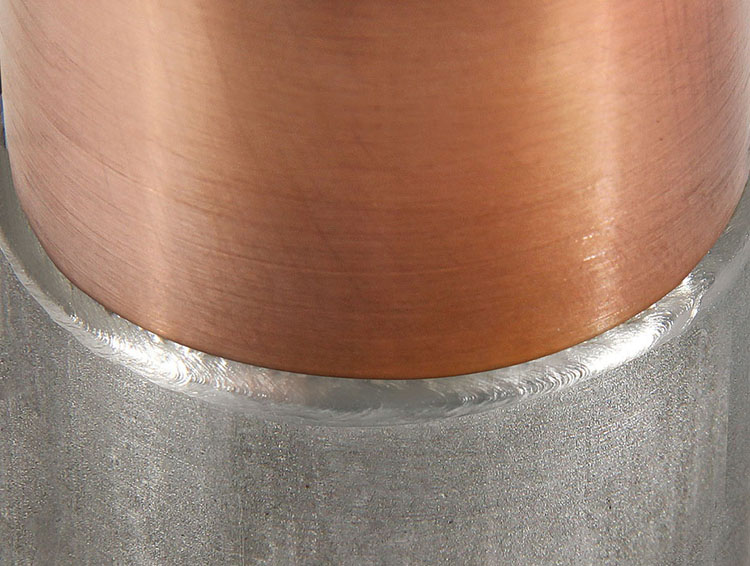

Muaj qee qhov teeb meem tshwm sim hauv qhov sib txawv ntawm cov hlau vuam uas cuam tshuam nws txoj kev loj hlob, xws li kev muaj pes tsawg leeg thiab kev ua tau zoo ntawm qhov sib txawv ntawm qhov sib txawv ntawm cov hlau fusion.Feem ntau ntawm kev puas tsuaj rau qhov sib txawv ntawm cov hlau vuam qauv tshwm sim hauv thaj tsam fusion.Vim muaj qhov sib txawv crystallization yam ntxwv ntawm cov welds nyob rau hauv txhua seem nyob ze ntawm lub fusion zone, Nws kuj yog ib qho yooj yim los tsim ib tug kev hloov txheej txheej nrog kev ua haujlwm tsis zoo thiab kev hloov pauv hauv kev sib xyaw.

Tsis tas li ntawd, vim lub sijhawm ntev ntawm qhov kub thiab txias, cov txheej txheem diffusion hauv cheeb tsam no yuav nthuav dav, uas yuav ua rau cov hlau tsis sib xws ntxiv.Tsis tas li ntawd, thaum cov hlau sib txawv yog welded los yog tom qab kev kho cua sov los yog kev ua haujlwm kub tom qab vuam, nws feem ntau pom tias cov pa roj carbon monoxide nyob rau sab qis "migrate" los ntawm cov ciaj ciam rau cov hlau alloy siab, tsim cov txheej txheem decarburization. ob sab ntawm txoj kab fusion.Thiab txheej txheej carburization, lub hauv paus hlau tsim cov txheej txheem decarburization ntawm sab qis alloy, thiab cov txheej txheem carburization ua rau ntawm qhov siab alloy weld sab.

Obstacles thiab teeb meem rau kev siv thiab kev loj hlob ntawm dissimilar hlau qauv yog manifested nyob rau hauv cov nram qab no yam:

1. Nyob rau hauv chav tsev kub, cov khoom siv kho tshuab (xws li tensile, cuam tshuam, dabtsi yog khoov, thiab lwm yam) ntawm qhov sib koom ua ke ntawm cov hlau sib txawv yog feem ntau zoo dua li cov hlau hauv paus yuav tsum tau welded.Txawm li cas los xij, ntawm qhov kub thiab txias los yog tom qab kev ua haujlwm ntev ntawm qhov kub thiab txias, qhov kev ua haujlwm ntawm qhov sib koom ua ke yog qis dua ntawm cov hlau puag.khoom.

2. Muaj qhov hloov pauv martensite ntawm austenite weld thiab pearlite puag hlau.Cov cheeb tsam no muaj tsawg toughness thiab yog ib tug high-hardness brittle txheej.Nws kuj yog ib qho chaw tsis muaj zog uas ua rau cov khoom tsis ua haujlwm thiab kev puas tsuaj.Nws yuav txo cov welded qauv.kev ntseeg tau ntawm kev siv.

3. Carbon migration thaum lub sij hawm tom qab kev kho cua sov los yog kev ua haujlwm kub yuav ua rau cov txheej txheem carburized thiab decarburized txheej ntawm ob sab ntawm fusion kab.Nws feem ntau ntseeg tau tias qhov txo qis ntawm cov pa roj carbon monoxide hauv decarburized txheej yuav ua rau muaj kev hloov pauv loj (feem ntau tsis zoo) hauv cov qauv thiab kev ua haujlwm ntawm thaj chaw, ua rau thaj chaw no muaj kev ua haujlwm tsis zoo thaum lub sijhawm ua haujlwm.Qhov tsis ua hauj lwm ntawm ntau cov kav dej kub kub hauv kev pabcuam lossis hauv kev sim yog tsom rau hauv txheej decarburization.

4. Kev ua tsis tiav yog muaj feem xyuam rau cov xwm txheej xws li lub sijhawm, qhov kub thiab txias hloov pauv.

5. Kev kho cua sov tom qab vuam tsis tuaj yeem tshem tawm cov kev ntxhov siab uas nyob hauv qhov sib koom ua ke.

6. Inhomogeneity ntawm tshuaj muaj pes tsawg leeg.

Thaum cov hlau tsis sib xws yog welded, txij li cov hlau ntawm ob sab ntawm lub vuam thiab cov hlau alloy ntawm cov vuam yog qhov sib txawv, thaum lub sij hawm vuam txheej txheem, cov hlau thiab cov khoom siv vuam yuav yaj thiab sib tov.Lub uniformity ntawm qhov sib tov yuav hloov nrog kev hloov ntawm cov txheej txheem vuam.Cov kev hloov pauv, thiab kev sib xyaw ua ke kuj tseem txawv heev ntawm cov haujlwm sib txawv ntawm qhov sib koom ua ke, uas ua rau muaj qhov tsis sib xws ntawm cov tshuaj muaj pes tsawg leeg ntawm cov khoom sib txuas.

7. Inhomogeneity ntawm metallographic qauv.

Vim qhov tsis sib xws ntawm cov tshuaj muaj pes tsawg leeg ntawm cov welded sib koom, tom qab muaj kev sib tw vuam thermal, cov qauv sib txawv tshwm sim nyob rau hauv txhua qhov chaw ntawm cov welded sib koom, thiab cov koom haum tsis tshua muaj kev sib koom ua ke feem ntau tshwm sim hauv qee qhov chaw.

8. Kev ua haujlwm tsis tu ncua.

Qhov sib txawv ntawm cov tshuaj muaj pes tsawg leeg thiab cov qauv metallographic ntawm cov pob qij txha welded coj txog cov khoom sib txawv ntawm cov pob qij txha welded.Lub zog, hardness, plasticity, toughness, cuam tshuam cov khoom, siab kub creep, thiab durability zog ntawm ntau qhov chaw raws lub welded sib koom yog txawv heev.Qhov kev tsis sib haum xeeb tseem ceeb no ua rau thaj chaw sib txawv ntawm qhov sib koom ua ke coj txawv txawv nyob rau hauv tib yam kev mob, nrog rau thaj chaw tsis muaj zog thiab cov cheeb tsam muaj zog tshwm sim.Tshwj xeeb tshaj yog nyob rau hauv qhov kub thiab txias, sib txawv hlau welded pob qij txha yog nyob rau hauv kev pab cuam thaum lub sij hawm kev pab cuam.Kev ua tsis tiav thaum ntxov feem ntau tshwm sim.

Cov yam ntxwv ntawm cov txheej txheem vuam sib txawv thaum vuam cov hlau tsis sib xws

Feem ntau txoj kev vuam siv tau rau vuam sib txawv ntawm cov hlau, tab sis thaum xaiv cov txheej txheem vuam thiab tsim cov txheej txheem ntsuas, cov yam ntxwv ntawm cov hlau tsis sib xws tseem yuav tsum tau txiav txim siab.Raws li cov kev cai sib txawv ntawm lub hauv paus hlau thiab welded pob qij txha, fusion vuam, siab vuam thiab lwm yam vuam txoj kev yog tag nrho cov siv nyob rau hauv dissimilar hlau vuam, tab sis txhua tus muaj nws tus kheej zoo thiab tsis zoo.

1. Vuam

Feem ntau siv fusion vuam txoj hauv kev sib txawv hlau vuam yog electrode arc vuam, submerged arc vuam, roj shielded arc vuam, electroslag vuam, plasma arc vuam, electron beam vuam, laser vuam, thiab lwm yam. piv los yog tswj cov melting npaum li cas ntawm cov khoom siv hlau sib txawv, electron beam welding, laser vuam, plasma arc vuam thiab lwm txoj kev uas muaj ntau dua qhov kub ntawm lub zog ceev yuav siv tau.

Txhawm rau txo qhov nkag mus tob, kev ntsuas thev naus laus zis xws li indirect arc, viav vias vuam hlau, sawb electrode, thiab lwm yam tsis muaj zog vuam hlau tuaj yeem siv tau.Tab sis tsis muaj teeb meem dab tsi, tsuav yog nws yog fusion vuam, ib feem ntawm lub hauv paus hlau yuav ib txwm yaj mus rau hauv lub vuam thiab ua rau dilution.Tsis tas li ntawd, cov tshuaj intermetallic, eutectics, thiab lwm yam yuav raug tsim.Yuav kom txo tau cov teebmeem tsis zoo no, lub sijhawm nyob ntawm cov hlau nyob hauv cov kua lossis cov khoom kub kub hauv lub xeev yuav tsum tau tswj thiab ua kom luv.

Txawm li cas los xij, txawm tias muaj kev txhim kho txuas ntxiv thiab txhim kho cov txheej txheem vuam thiab cov txheej txheem ntsuas, nws tseem nyuaj los daws txhua yam teeb meem thaum vuam sib txawv ntawm cov hlau, vim tias muaj ntau hom hlau, ntau yam kev ua tau zoo, thiab cov ntawv sib txawv.Feem ntau, nws yog ib qho tsim nyog yuav tsum tau siv lub siab vuam los yog lwm txoj kev vuam siv los daws cov teeb meem vuam ntawm cov pob qij txha tshwj xeeb sib txawv.

2. Siab vuam

Feem ntau txoj kev vuam siab tsuas yog ua kom sov cov hlau kom welded rau lub xeev yas lossis txawm tias tsis sov nws, tab sis siv qee qhov siab raws li qhov yooj yim feature.Piv nrog fusion vuam, siab vuam muaj qee qhov zoo thaum vuam sib txawv ntawm cov hlau sib txuas.Ntev npaum li daim ntawv sib koom ua ke tso cai thiab qhov vuam zoo tuaj yeem ua tau raws li qhov yuav tsum tau ua, kev siv vuam siab feem ntau yog qhov kev xaiv tsim nyog.

Thaum lub sij hawm vuam siab, qhov chaw sib txuas ntawm cov hlau tsis sib xws yuav los yog tsis yaj.Txawm li cas los xij, vim tias cov nyhuv ntawm lub siab, txawm tias muaj cov hlau molten nyob rau saum npoo, nws yuav raug extruded thiab tawm (xws li flash welding thiab kev sib txhuam vuam).Tsuas yog nyob rau hauv ob peb kis Ib zaug molten hlau tseem nyob tom qab siab vuam (xws li chaw vuam).

Txij li thaum lub siab vuam tsis kub los yog cov cua kub kub tsis tshua muaj, nws muaj peev xwm txo los yog tsis txhob muaj kev phiv los ntawm thermal cycles ntawm cov hlau yam ntxwv ntawm lub hauv paus hlau thiab tiv thaiv cov tiam ntawm brittle intermetallic tebchaw.Qee cov ntaub ntawv ntawm lub siab vuam tuaj yeem nyem qhov sib txuas intermetallic uas tau tsim tawm ntawm qhov sib koom ua ke.Tsis tas li ntawd, tsis muaj teeb meem ntawm kev hloov pauv ntawm cov khoom ntawm cov hlau welded los ntawm dilution thaum lub sij hawm vuam siab.

Txawm li cas los xij, feem ntau txoj kev siv vuam siab muaj qee yam yuav tsum tau ua rau daim ntawv sib koom ua ke.Piv txwv li, qhov chaw welding, seam welding, thiab ultrasonic vuam yuav tsum siv cov pob qij txha;Thaum sib txhuam vuam, yam tsawg kawg ib qho workpiece yuav tsum muaj ib tug rotating lub cev cross-section;Kev tawg vuam tsuas yog siv tau rau kev sib txuas ntawm thaj tsam loj, thiab lwm yam. Cov khoom siv vuam vuam tsis tau nrov.Cov no undoubtedly txwv qhov kev thov ntawm lub siab welding.

3. Lwm txoj kev

Ntxiv nrog rau fusion vuam thiab siab vuam, muaj ntau txoj hauv kev uas tuaj yeem siv los ua cov hlau sib txawv.Piv txwv li, brazing yog ib txoj hauv kev sib txawv ntawm cov hlau sib txawv ntawm cov khoom siv hlau thiab cov hlau hauv paus, tab sis qhov uas tau tham ntawm no yog txoj hauv kev tshwj xeeb dua brazing.

Muaj ib txoj kev hu ua fusion welding-brazing, uas yog, qis-melting-point hlau sab ntawm cov hlau sib txuas yog fusion-welded, thiab high-melting-point hlau sab yog brazed.Thiab feem ntau cov hlau tib yam li cov khoom siv uas tsis tshua muaj melting point yog siv los ua cov solder.Yog li ntawd, cov txheej txheem vuam ntawm lub brazing muab tub lim hlau thiab qis melting point puag hlau yog tib yam hlau, thiab tsis muaj teeb meem tshwj xeeb.

Cov txheej txheem brazing yog nruab nrab ntawm cov hlau muab tub lim thiab lub siab melting point puag hlau.Lub hauv paus hlau tsis yaj los yog crystallize, uas tuaj yeem zam ntau yam teeb meem weldability, tab sis cov hlau muab tub lim yuav tsum muaj peev xwm ntub lub hauv paus hlau zoo.

Lwm txoj kev hu ua eutectic brazing lossis eutectic diffusion brazing.Qhov no yog los ua kom sov qhov chaw sib cuag ntawm cov hlau tsis sib xws rau qhov kub thiab txias, kom ob lub hlau tsim ib qho qis-melting-point eutectic ntawm qhov chaw sib cuag.Qhov qis-melting-point eutectic yog kua ntawm qhov kub thiab txias, qhov tseem ceeb los ua ib hom solder yam tsis tas yuav tsum tau rau sab nraud solder.Txoj kev brazing.

Tau kawg, qhov no yuav tsum tau tsim kom muaj qhov qis-melting-point eutectic ntawm ob lub hlau.Thaum lub sij hawm diffusion vuam ntawm cov hlau tsis sib xws, cov khoom nruab nrab nruab nrab yog ntxiv, thiab cov khoom nruab nrab txheej yog rhuab nyob rau hauv qhov tsis tshua muaj siab kom yaj, los yog tsim ib qho qis melting point eutectic nyob rau hauv kev sib cuag nrog cov hlau yuav tsum tau welded.Cov txheej nyias nyias ntawm cov kua tsim nyob rau lub sijhawm no, tom qab qee lub sijhawm ntawm cov txheej txheem tiv thaiv tshav kub, ua rau cov khoom nruab nrab ntawm cov txheej txheem yaj.Thaum tag nrho cov txheej txheem txheej nruab nrab yog diffused rau hauv cov khoom siv hauv paus thiab homogenized, qhov sib txawv ntawm cov hlau sib txuas yam tsis muaj cov khoom nruab nrab tuaj yeem tsim.

Hom kev no yuav tsim cov kua hlau me me thaum lub sij hawm vuam txheej txheem.Yog li ntawd, nws tseem hu ua kua theem hloov welding.Lawv qhov tshwj xeeb yog tias tsis muaj cov qauv casting hauv kev sib koom ua ke.

Tej yam uas yuav tsum tau nco ntsoov thaum welding dissimilar hlau

1. Xav txog lub cev, txhua yam khoom thiab tshuaj muaj pes tsawg leeg ntawm cov vuam

(1) Los ntawm qhov kev xav ntawm qhov sib npaug ntawm lub zog, xaiv cov welding rods uas ua tau raws li cov khoom siv ntawm lub hauv paus hlau, los yog muab cov weldability ntawm lub hauv paus hlau nrog cov vuam rods uas tsis sib npaug ntawm lub zog thiab zoo weldability, tab sis xav txog cov qauv ntawm cov qauv. weld kom tau raws li qhov sib npaug zog.Lub zog thiab lwm yam kev xav tau nruj.

(2) Ua kom nws cov alloy muaj pes tsawg leeg zoo ib yam nrog lossis ze rau cov khoom siv hauv paus.

(3) Thaum lub hauv paus hlau muaj siab C, S, thiab P tsis zoo impurities, vuam rods uas zoo dua tawg kuj thiab porosity kuj yuav tsum tau xaiv.Nws raug nquahu kom siv calcium titanium oxide electrode.Yog tias nws tseem tsis tuaj yeem daws tau, qhov qis hydrogen sodium hom vuam pas nrig tuaj yeem siv tau.

2. Xav txog kev ua haujlwm thiab kev ua haujlwm ntawm cov khoom siv vuam

(1) Nyob rau hauv cov xwm txheej ntawm bearing dynamic load thiab cuam tshuam load, ntxiv rau kom ntseeg tau lub zog, muaj siab yuav tsum tau rau tej yam toughness thiab elongation.Tsawg hydrogen hom, calcium titanium hom thiab hlau oxide hom electrodes yuav tsum tau xaiv ib zaug.

(2) Yog hais tias nyob rau hauv kev sib cuag nrog corrosive xov xwm, tsim nyog stainless hlau vuam rods yuav tsum tau xaiv raws li hom, concentration, ua hauj lwm kub ntawm cov xov xwm, thiab seb nws yog dav siv khaub ncaws los yog intergranular corrosion.

(3) Thaum ua haujlwm nyob rau hauv kev hnav khaub ncaws, nws yuav tsum paub qhov txawv ntawm qhov nws yog qhov qub lossis cuam tshuam, thiab seb nws puas hnav ntawm qhov kub thiab txias.

(4) Thaum ua haujlwm nyob rau hauv qhov tsis muaj qhov kub thiab txias, cov khoom siv vuam sib txuas uas ua kom cov khoom siv hluav taws xob qis lossis kub siab yuav tsum raug xaiv.

3. Xav txog qhov nyuaj ntawm kev sib sau ua ke ntawm cov khoom siv vuam, qhov nruj, kev npaj ntawm vuam tawg thiab vuam txoj hauj lwm.

(1) Rau weldments nrog cov duab nyuaj lossis cov tuab loj, qhov kev ntxhov siab ntawm cov hlau vuam thaum lub sij hawm txias yog qhov loj thiab cov kab nrib pleb yuav tshwm sim.Vuam rods uas muaj zog tawg yuav tsum tau xaiv, xws li qis-hydrogen vuam rods, high-toughness vuam rods los yog hlau oxide vuam pas nrig.

(2) Rau weldments uas tsis tuaj yeem tig rov qab vim yog qhov xwm txheej, vuam rods uas tuaj yeem welded hauv txhua txoj haujlwm yuav tsum raug xaiv.

(3) Rau vuam qhov uas nyuaj rau kev ntxuav, siv acidic vuam rods uas yog heev oxidizing thiab insensitive rau nplai thiab roj kom tsis txhob muaj qhov tsis xws luag xws li pores.

4. Xav txog cov khoom siv vuam vuam

Nyob rau hauv qhov chaw uas tsis muaj DC vuam tshuab, nws tsis pom zoo kom siv vuam rods nrog txwv DC fais fab mov.Hloov chaw, vuam rods nrog AC thiab DC fais fab mov yuav tsum tau siv.Qee cov hlau (xws li pearlitic tshav kub-resistant steel) yuav tsum tau tshem tawm cov thermal kev nyuaj siab tom qab vuam, tab sis tsis tuaj yeem kho cua sov vim cov khoom siv (los yog cov kev txwv ntawm cov qauv).Vuam pas nrig ua los ntawm cov khoom siv hlau tsis yog hlau (xws li austenitic stainless hlau) yuav tsum tau siv los hloov, thiab kev kho cua sov tom qab vuam tsis tsim nyog.

5. Xav txog kev txhim kho cov txheej txheem vuam thiab tiv thaiv cov neeg ua haujlwm noj qab haus huv

Qhov twg ob qho tib si acidic thiab alkaline electrodes tuaj yeem ua tau raws li qhov yuav tsum tau ua, acidic electrodes yuav tsum tau siv ntau li ntau tau.

6. Xav txog kev ua haujlwm ntawm kev tsim khoom thiab kev lag luam rationality

Nyob rau hauv cov ntaub ntawv ntawm kev ua tau zoo tib yam, peb yuav tsum tau sim siv cov nqi qis acidic vuam rods es tsis txhob alkaline vuam rods.Ntawm cov acidic vuam pas nrig, titanium hom thiab titanium-calcium hom yog kim tshaj plaws.Raws li qhov xwm txheej ntawm kuv lub teb chaws cov peev txheej ntxhia, titanium hlau yuav tsum tau txhawb nqa kom muaj zog.Coated welding pas nrig.

Post lub sij hawm: Oct-27-2023