Taw qhia

Raws li lub tsheb lub cev yog tus nqa khoom ntawm lwm qhov ntawm lub tsheb, nws cov cuab yeej tsim khoom ncaj qha txiav txim siab tag nrho kev tsim khoom zoo ntawm lub tsheb.Vuam yog ib qho tseem ceeb ntawm cov txheej txheem tsim khoom hauv cov txheej txheem ntawm kev tsim tsheb lub cev.Tam sim no, cov vuam thev naus laus zis siv rau lub tsheb lub cev vuam feem ntau suav nrog qhov chaw vuam, MIG vuam, MAG vuam thiab laser vuam.

Laser vuam tshuab raws li kev siv tshuab optoelectromechanical integration vuam tshuab, piv nrog cov tsoos tsheb lub cev vuam tshuab, muaj qhov zoo ntawm lub zog ceev ceev, vuam ceev, me me vuam kev nyuaj siab thiab deformation, thiab zoo yooj.

Cov qauv ntawm lub tsheb lub cev yog complex, thiab nws cov khoom yog feem ntau nyias-walled thiab nkhaus.Lub tsheb lub cev vuam yog ntsib nrog qee qhov teeb meem, xws li kev hloov pauv ntawm cov khoom siv hauv lub cev, qhov sib txawv ntawm lub cev qhov chaw, ntau hom vuam trajectory thiab cov ntaub ntawv sib koom ua ke.Tsis tas li ntawd, lub tsheb lub cev vuam muaj qhov yuav tsum tau ua ntawm vuam zoo thiab vuam efficiency.

Raws li cov txheej txheem vuam tsim nyog, laser vuam tuaj yeem ua kom lub zog qaug zog thiab cuam tshuam rau cov khoom tseem ceeb ntawm lub cev lub cev, thiaj li ua kom cov vuam zoo thiab kev pab cuam lub neej ntawm lub tsheb lub cev.Laser vuam tshuab tuaj yeem hloov kho rau ntau hom kev sib koom ua ke, cov thicknesses sib txawv thiab cov khoom sib txawv ntawm nws pib lub cev qhov chaw vuam, kom ua tau raws li cov kev xav tau ntawm nws pib lub cev tsim.Yog li ntawd, laser vuam tshuab yog ib qho tseem ceeb kev txhais tau tias kom ua tiav kev loj hlob zoo ntawm kev lag luam tsheb.

Laser vuam tshuab ntawm tsheb lub cev

Laser sib sib zog nqus nqus vuam tshuab ntawm lub tsheb lub cev

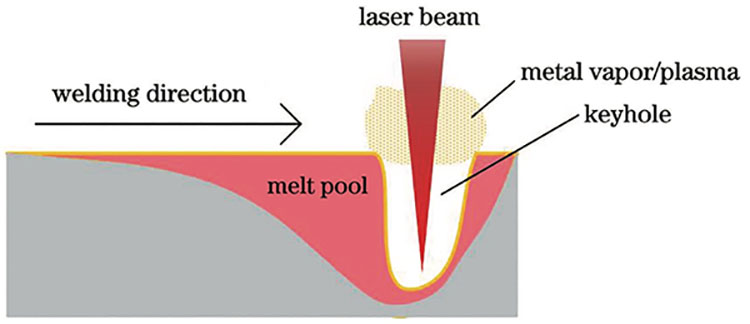

Lub hauv paus ntsiab lus ntawm laser sib sib zog nqus nqus vuam txheej txheem (Daim duab 1) yog raws li nram no: thaum lub laser zog ceev mus txog ib tug tej theem, lub nto ntawm cov khoom vaporizes, tsim ib tug keyhole.Thaum cov hlau vapor siab nyob rau hauv lub qhov mus txog ib tug dynamic tshuav nyiaj li cas nrog lub static siab thiab nto nro ntawm cov kua nyob ib puag ncig, lub laser yuav irradiated mus rau hauv qab ntawm lub qhov los ntawm lub keyhole, thiab nrog rau lub zog ntawm lub laser beam, ib tug nruam weld yog tsim.Thaum lub sij hawm laser sib sib zog nqus welding txheej txheem, tsis tas yuav ntxiv auxiliary flux los yog muab tub lim, thiab lub workpiece tus kheej cov ntaub ntawv tuaj yeem welded ua ke.

FIG.1 Schematic daim duab ntawm laser sib sib zog nqus nqus vuam txheej txheem

Lub vuam tau txais los ntawm laser sib sib zog nqus nqus vuam yog feem ntau du thiab ncaj, thiab deformation yog me me, uas yog qhov tsim nyog rau kev txhim kho qhov raug ntawm lub tsheb lub cev.Lub siab tensile lub zog ntawm lub vuam ua kom lub vuam zoo ntawm lub tsheb lub cev.Qhov vuam ceev yog ceev, uas yog qhov zoo rau kev txhim kho vuam ntau lawm efficiency.

Nyob rau hauv cov txheej txheem ntawm lub tsheb lub cev vuam, kev siv laser sib sib zog nqus nqus vuam txheej txheem tuaj yeem txo tus naj npawb ntawm cov khoom, pwm thiab vuam cov cuab yeej, yog li txo lub cev hnyav thiab cov nqi tsim khoom.Txawm li cas los xij, cov txheej txheem laser sib sib zog nqus nqus vuam muaj qhov tsis zoo rau kev sib dhos ntawm cov khoom sib txuas, thiab qhov sib dhos sib dhos yuav tsum tau tswj ntawm 0.05 thiab 2 hli.Yog tias qhov sib dhos sib dhos loj dhau lawm, qhov vuam tsis xws li qhov pores yuav tshwm sim.

Cov kev tshawb fawb tam sim no qhia tau hais tias cov vuam nrog zoo nto tsim, tsis tshua muaj qhov tsis xws luag thiab cov khoom siv zoo heev tuaj yeem tau txais los ntawm kev ua kom zoo dua cov txheej txheem ntawm laser sib sib zog nqus nqus vuam hauv vuam ntawm tib yam khoom ntawm lub tsheb lub cev.Cov cuab yeej zoo heev ntawm cov vuam tuaj yeem ua tau raws li qhov xav tau ntawm cov khoom siv vuam ntawm lub tsheb lub cev.Txawm li cas los xij, hauv tsheb lub cev vuam, qhov sib txawv ntawm cov hlau laser sib sib zog nqus nqus vuam tshuab sawv cev los ntawm aluminium alloy thiab hlau tsis paub tab.Txawm hais tias vuam seams nrog kev ua tau zoo heev tuaj yeem tau txais los ntawm kev ntxiv cov txheej txheem hloov pauv, cov txheej txheem cuam tshuam ntawm cov txheej txheem sib txawv ntawm IMC txheej thiab lawv cov txheej txheem kev ua haujlwm ntawm vuam microstructure tsis meej, thiab xav tau kev tshawb fawb ntxiv.

Tsheb lub cev laser hlau filling vuam txheej txheem

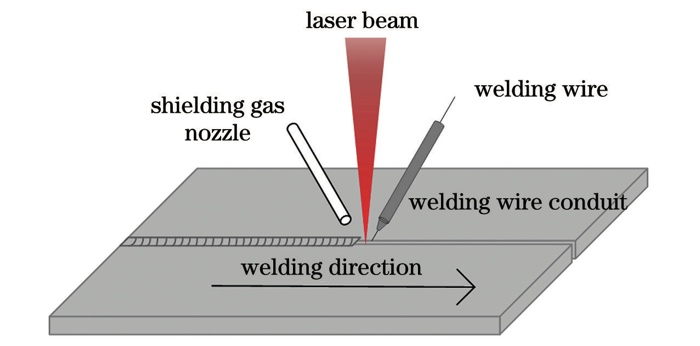

Lub hauv paus ntsiab lus ntawm laser muab tub lim hlau vuam txheej txheem yog raws li nram no: ib tug welded sib koom ua ke yog tsim los ntawm pre-filling ib tug tshwj xeeb vuam hlau nyob rau hauv lub vuam los yog pub lub vuam hlau ib txhij nyob rau hauv lub laser vuam txheej txheem.Qhov no yog sib npaug rau inputting kwv yees li homogeneous vuam hlau cov khoom rau hauv lub pas dej ua ke thaum lub sij hawm laser sib sib zog nqus nqus vuam.Lub schematic daim duab ntawm lub laser muab tub lim hlau vuam txheej txheem yog qhia nyob rau hauv daim duab 2.

FIG.2 Schematic daim duab ntawm laser xaim filling vuam txheej txheem

Piv nrog rau laser sib sib zog nqus nqus vuam, laser hlau filling vuam muaj ob qhov zoo hauv nws lub cev vuam: ua ntej, nws tuaj yeem txhim kho qhov siab ntev ntawm kev sib dhos ntawm lub cev qhov chaw yuav tsum tau welded, thiab daws qhov teeb meem uas lub laser sib sib zog nqus nqus vuam. yuav tsum tau tshem tawm groove ntau dhau;Qhov thib ob, cov ntaub so ntswg ntawm thaj chaw weld tuaj yeem txhim kho los ntawm kev siv cov vuam hlau nrog cov ntsiab lus sib txawv, thiab tom qab ntawd qhov kev ua haujlwm vuam tuaj yeem tswj tau.

Nyob rau hauv cov txheej txheem ntawm kev tsim tsheb lub cev, lub laser xaim filling vuam txheej txheem yog tsuas yog siv rau vuam aluminium alloy thiab steel qhov chaw ntawm lub cev.Tshwj xeeb tshaj yog nyob rau hauv cov txheej txheem vuam ntawm aluminium alloy qhov chaw ntawm lub tsheb lub cev, qhov nro ntawm lub pas dej molten yog me me, uas yog ib qho yooj yim ua rau lub cev qhuav dej ntawm lub pas dej molten, thiab cov txheej txheem laser hlau filling vuam tuaj yeem daws qhov teeb meem ntawm lub pas dej molten. los ntawm melting lub vuam hlau.

Laser brazing tshuab ntawm tsheb lub cev

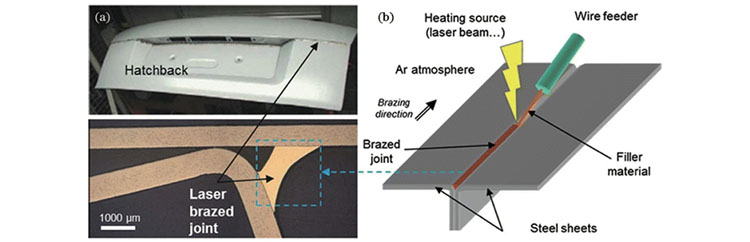

Lub hauv paus ntsiab lus ntawm laser brazing txheej txheem yog raws li nram no: lub laser yog siv los ua lub tshav kub qhov chaw, lub laser beam yog illuminated rau saum npoo ntawm vuam hlau tom qab raug tsom, welding hlau yog melted, lub melted hlau tee thiab puv ntawm cov qhov chaw yuav tsum tau welded, thiab metallurgical teebmeem xws li melting thiab diffusion tshwm sim ntawm cov muab tub lim hlau thiab lub workpiece, kom lub workpiece txuas nrog.Tsis zoo li cov txheej txheem laser hlau filling vuam, cov txheej txheem laser brazing tsuas yog yaj cov hlau thiab tsis yaj lub workpiece yuav tsum tau welded.Laser brazing muaj qhov zoo welding stability, tab sis lub zog tensile ntawm vuam yog tsawg.FIG.3 qhia txog daim ntawv thov ntawm laser brazing txheej txheem hauv tsheb khau raj hau vuam.

FIG.3 Daim ntawv thov ntawm laser brazing nyob rau hauv lub tsheb: (a) laser vuam ntawm rear hood;(b) Schematic daim duab ntawm laser brazing

Nyob rau hauv cov txheej txheem ntawm lub tsheb lub cev welding, laser brazing txheej txheem yog tsuas yog welding lub cev qhov chaw uas tsis muaj kev sib koom ua ke yuav tsum muaj zog, xws li vuam ntawm lub sab saum toj cover thiab sab phab ntsa ntawm lub cev, lub vuam ntawm lub sab sauv thiab sab ntawm lub cev. npog, thiab lwm yam., Volkswagen, Audi thiab lwm yam high-end qauv ntawm sab saum toj npog yog siv laser brazing txheej txheem.

Lub ntsiab tsis xws luag nyob rau hauv laser brazing vuam seam ntawm lub tsheb lub cev muaj xws li ntug tom, porosity, weld deformation, thiab lwm yam. Cov tsis xws luag yuav suppressed obviously los ntawm kev kho cov txheej txheem tsis thiab siv multi-focus laser brazing txheej txheem.

Laser arc composite vuam tshuab ntawm tsheb lub cev

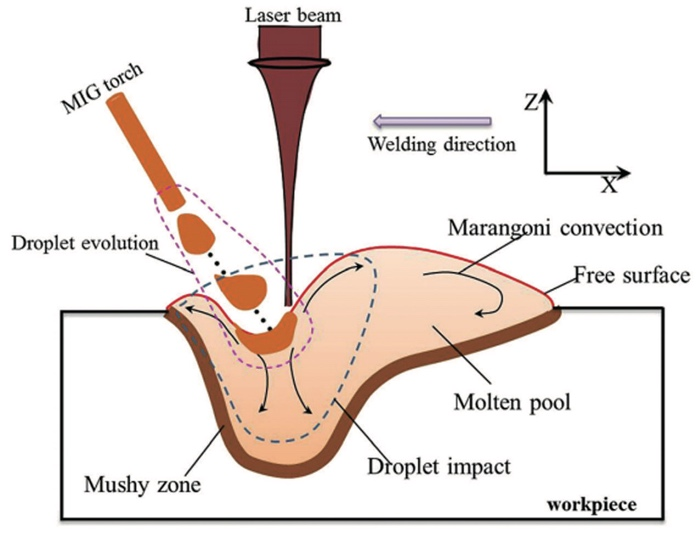

Lub hauv paus ntsiab lus ntawm laser-arc composite welding txheej txheem yog raws li nram no: siv ob lub tshav kub qhov chaw ntawm laser thiab arc los ua nyob rau saum npoo ntawm lub workpiece yuav tsum tau welded tib lub sij hawm, lub workpiece yog melted thiab solidified los tsim ib tug weld.Daim duab 4 qhia txog schematic daim duab ntawm laser-arc composite vuam txheej txheem.

FIG.4 Schematic daim duab ntawm laser-arc composite vuam txheej txheem

Laser-arc composite welding muaj qhov zoo ntawm ob qho tib si laser vuam thiab arc vuam: ua ntej, nyob rau hauv qhov kev txiav txim ntawm ob chav kub qhov chaw, qhov vuam ceev yog zoo dua, lub tshav kub input me me, vuam deformation me me, thiab cov yam ntxwv ntawm laser vuam. khaws cia;Qhov thib ob, nws muaj peev xwm txuas tau zoo dua thiab ua siab ntev dua ntawm kev sib dhos sib dhos;Thib peb, tus nqi solidification ntawm lub pas dej molten yog qeeb, uas yog qhov tsim nyog rau kev tshem tawm qhov tsis xws luag xws li qhov pores thiab tawg, thiab txhim kho cov qauv thiab kev ua haujlwm ntawm thaj chaw tshav kub.Plaub, vim yog cov nyhuv ntawm arc, nws tuaj yeem vuam cov ntaub ntawv nrog kev xav tau siab thiab thermal conductivity, thiab ntau yam ntawm cov ntaub ntawv siv tau dav dua.

Nyob rau hauv cov txheej txheem ntawm kev tsim tsheb lub cev, lub laser-arc composite vuam txheej txheem yog tsuas yog rau weld aluminium alloy Cheebtsam ntawm lub cev thiab txhuas-steel dissimilar hlau, thiab vuam yog ua rau qhov chaw nrog loj sib dhos, xws li vuam ntawm qhov chaw. lub qhov rooj tsheb, vim tias qhov sib dhos sib dhos yog qhov tsim nyog rau kev ua si ntawm tus choj kev ua haujlwm ntawm laser-arc composite vuam.Tsis tas li ntawd, laser-MIG arc composite vuam thev naus laus zis kuj tseem siv rau sab saum toj beam txoj hauj lwm ntawm Audi lub cev.

Nyob rau hauv tus txheej txheem ntawm lub tsheb lub cev welding, laser-arc composite welding muaj qhov zoo ntawm qhov sib txawv ntau dua li ib lub laser vuam, tab sis tus txheeb ze txoj hauj lwm ntawm laser thiab arc, laser welding tsis, arc tsis thiab lwm yam yuav tsum tau txiav txim siab comprehensively.Lub tshav kub thiab huab hwm coj hloov pauv hauv laser-arc vuam yog qhov nyuaj, tshwj xeeb tshaj yog cov txheej txheem ntawm kev tswj hwm lub zog thiab IMC thickness thiab cov qauv kev cai hauv cov khoom siv vuam sib txawv tseem tsis paub meej, thiab xav tau kev tshawb fawb ntxiv.

Lwm yam automotive lub cev laser vuam txheej txheem

Laser sib sib zog nqus nkag welding, laser hlau filling vuam, laser brazing thiab laser-arc composite vuam thiab lwm yam txheej txheem vuam tau paub ntau dua txoj kev xav thiab kev siv dav dav.Nrog rau kev txhim kho ntawm kev lag luam automotive cov kev cai rau kev ua haujlwm ntawm lub cev vuam thiab qhov nce ntawm qhov kev thov rau cov khoom sib txawv ntawm cov khoom siv hauv kev tsim tsheb, laser chaw vuam, laser viav vias vuam, ntau lub laser beam welding thiab laser ya davhlau vuam tau them xim. rau.

Laser qhov chaw vuam txheej txheem

Laser chaw vuam yog ib qho kev siv tshuab laser welding, uas muaj qhov zoo ntawm vuam ceev thiab siab vuam precision.Lub hauv paus ntsiab lus ntawm laser chaw welding yog tsom lub laser beam mus rau ib qho taw tes ntawm qhov yuav tsum tau welded, kom cov hlau ntawm lub point yog instantly yaj, los ntawm kev kho lub laser ceev kom ua tau thermal conduction vuam los yog sib sib zog nqus fusion vuam nyhuv. , thaum lub laser beam nres, cov kua hlau reflow, solidified los ua ib qho kev sib koom ua ke.

Muaj ob yam tseem ceeb ntawm laser chaw vuam: pulsed laser chaw vuam thiab nruam laser chaw vuam.Pulsed laser chaw vuam laser beam ncov lub zog yog siab, tab sis lub sijhawm ua haujlwm luv luv, feem ntau yog siv rau magnesium alloy, aluminium alloy thiab lwm lub teeb hlau vuam.Lub zog nruab nrab ntawm lub teeb ntawm laser nyob rau hauv tas li laser qhov chaw vuam yog siab, lub laser txiav txim lub sij hawm ntev, thiab nws yog dav siv nyob rau hauv steel welding.

Nyob rau hauv cov nqe lus ntawm lub tsheb lub cev vuam, piv nrog rau qhov chaw vuam, laser chaw vuam muaj qhov zoo ntawm qhov tsis sib cuag, qhov chaw vuam trajectory tuaj yeem tsim los ntawm nws tus kheej, thiab lwm yam. tsheb lub cev cov ntaub ntawv.

Laser viav vias vuam txheej txheem

Laser viav vias vuam yog ib qho tshiab laser vuam tshuab tau npaj nyob rau hauv xyoo tas los no, uas tau muaj kev txhawj xeeb.Lub hauv paus ntsiab lus ntawm cov thev naus laus zis no yog: los ntawm kev sib koom ua ke ntawm pawg galvanometer ntawm lub laser vuam lub taub hau, lub laser beam sai sai, kev txiav txim siab thiab nyob rau hauv ib qho me me, thiaj li ua tiav cov nyhuv ntawm lub laser beam mus rau pem hauv ntej thaum nplawm.

Lub viav vias tseem ceeb hauv cov txheej txheem laser viav vias vuam muaj xws li viav vias viav vias, viav vias ntev, viav vias thiab viav vias tsis kawg.Cov txheej txheem laser viav vias vuam muaj qhov zoo tseem ceeb hauv kev vuam ntawm lub tsheb lub cev.Nyob rau hauv qhov kev txiav txim ntawm lub laser beam viav vias, lub ndlwg xeev ntawm lub molten pas dej ua ke yog ho hloov.Yog li ntawd, cov txheej txheem tsis tuaj yeem tsuas yog tshem tawm qhov tsis muaj qhov tsis xws luag, ua tiav cov txheej txheem ua kom zoo dua qub thiab txo cov porosity hauv vuam ntawm tib lub tsheb lub cev khoom.Tsis tas li ntawd, nws tseem tuaj yeem txhim kho cov teeb meem xws li kev sib xyaw tsis txaus ntawm cov khoom sib txawv thiab cov khoom siv tsis zoo ntawm cov welds nyob rau hauv vuam ntawm heterogeneous cov ntaub ntawv ntawm lub tsheb lub cev.

Multi-laser beam vuam txheej txheem

Tam sim no, cov fiber ntau optical laser tuaj yeem muab faib ua ntau lub laser kab teeb los ntawm ib qho splitter module ntsia rau hauv lub taub hau vuam.Multi-laser beam welding yog sib npaug rau kev siv ntau qhov chaw cua sov hauv cov txheej txheem vuam, los ntawm kev kho lub zog faib ntawm cov nqaj, cov kab teeb sib txawv tuaj yeem ua tiav cov haujlwm sib txawv, xws li: cov nqaj nrog lub zog siab dua yog cov nqaj loj, lub luag haujlwm sib sib zog nqus. nkag mus vuam;Lub zog qis dua ntawm cov nqaj tuaj yeem ntxuav thiab ua kom lub ntsej muag ntawm cov khoom siv, thiab ua kom lub zog nqus ntawm cov nqaj hlau los ntawm cov khoom siv.

Galvanized high-strength steel khoom yog dav siv nyob rau hauv lub tsheb lub cev.Multi-laser beam vuam thev naus laus zis tuaj yeem txhim kho tus cwj pwm evaporation ntawm zinc vapor thiab tus cwj pwm zoo ntawm lub pas dej molten hauv cov txheej txheem vuam ntawm galvanized steel phaj, txhim kho qhov teeb meem sputtering, thiab txhim kho lub zog tensile ntawm vuam.

Laser davhlau vuam txheej txheem

Lub laser ya dav hlau vuam tshuab yog ib qho tshiab laser vuam tshuab, uas muaj kev vuam zoo thiab tuaj yeem tsim los ntawm nws tus kheej.Lub hauv paus ntsiab lus ntawm laser ya davhlau vuam yog tias thaum lub laser beam tshwm sim ntawm X thiab Y tsom iav ntawm daim iav scanning, lub kaum sab xis ntawm daim iav yog tswj los ntawm kev ywj pheej programming kom ua tiav qhov deflection ntawm lub laser beam ntawm txhua lub kaum sab xis.

Cov tsoos laser vuam ntawm lub tsheb lub cev feem ntau yog nyob ntawm synchronous txav ntawm laser vuam lub taub hau tsav los ntawm vuam neeg hlau kom ua tiav vuam nyhuv.Txawm li cas los xij, qhov kev ua haujlwm vuam ntawm lub tsheb lub cev yog qhov hnyav heev los ntawm kev rov ua dua reciprocating suab ntawm vuam neeg hlau vim muaj coob tus welds thiab ntev ntev ntawm welds.Nyob rau hauv sib piv, laser davhlau welding tsuas yog yuav tsum tau kho lub kaum sab xis ntawm daim iav kom tiav vuam nyob rau hauv ib tug tej yam ntau yam.Yog li ntawd, laser ya dav hlau vuam tshuab tuaj yeem txhim kho qhov vuam efficiency thiab muaj cov ntawv thov dav dav.

Summary thiab prospect

Nrog rau txoj kev loj hlob ntawm kev lag luam tsheb, yav tom ntej lub cev vuam tshuab yuav txuas ntxiv txhim kho nyob rau hauv ob yam: vuam txheej txheem thiab ntse tshuab.

Lub tsheb lub cev, tshwj xeeb tshaj yog lub zog tshiab lub tsheb lub cev, tab tom txhim kho nyob rau hauv kev coj ntawm lub teeb.Lub teeb yuag, cov ntaub ntawv sib xyaw thiab cov ntaub ntawv sib txawv yuav siv dav hauv lub tsheb lub cev, cov txheej txheem laser vuam yog qhov nyuaj kom ua tau raws li nws cov kev xav tau vuam, yog li cov txheej txheem vuam zoo thiab siv tau zoo yuav dhau los ua qhov kev txhim kho yav tom ntej.

Nyob rau hauv xyoo tas los no, cov txheej txheem laser welding tshwm sim, xws li laser viav vias vuam, ntau lub laser beam vuam, laser davhlau vuam, thiab lwm yam, tau ua ntej kev tshawb fawb thiab kev tshawb fawb txog kev siv vuam zoo thiab vuam efficiency.Nyob rau hauv lub neej yav tom ntej, nws yog ib qho tsim nyog yuav tsum tau ua tib zoo sib txuas cov txheej txheem laser welding uas tshwm sim nrog cov khoom siv sib xws thiab cov khoom sib txawv ntawm lub cev ntawm lub tsheb, ua qhov kev tshawb fawb tob txog kev tsim ntawm laser beam viav vias trajectory, kev ua haujlwm ntawm ntau lub laser beam zog. thiab txhim kho lub davhlau vuam efficiency, thiab tshawb xyuas lub tsheb loj lub cev vuam txheej txheem.

Lub laser vuam tshuab ntawm lub tsheb lub cev yog sib sib zog nqus nrog cov cuab yeej ntse.Lub sijhawm tiag tiag ntawm kev xaav ntawm laser vuam lub xeev ntawm lub tsheb lub cev thiab kev tawm tswv yim tswj cov txheej txheem tsis ua lub luag haujlwm txiav txim siab hauv vuam zoo.Lub tshuab ntse laser vuam tam sim no feem ntau yog siv rau kev npaj ua ntej vuam trajectory thiab taug qab thiab tom qab vuam zoo soj ntsuam.Nyob rau hauv tsev thiab txawv teb chaws, kev tshawb fawb ntawm vuam tsis xws luag thiab parameter adaptive tswj yog tseem nyob rau hauv thawj theem, thiab laser vuam txheej txheem parameter adaptive tswj tshuab tsis tau siv nyob rau hauv lub tsheb lub cev manufacturing.

Yog li ntawd, nyob rau hauv saib ntawm daim ntawv thov yam ntxwv ntawm laser vuam tshuab nyob rau hauv tus txheej txheem ntawm lub tsheb lub cev vuam, ib tug ntse sensing system rau laser vuam nrog advanced multi-sensors raws li cov tub ntxhais thiab ib tug high-ceev thiab high-precision vuam neeg hlau tswj system yuav tsum tau. tsim nyob rau hauv lub neej yav tom ntej los xyuas kom meej lub real-time thiab raug ntawm txhua yam ntawm ntse laser vuam tshuab.Qhib qhov txuas ntawm "kev npaj ua ntej-welding trajectory - parameter adaptive control of welding quality online detection after welding" kom ntseeg tau tias kev ua tau zoo thiab ua tau zoo.

Post lub sij hawm: Oct-16-2023