Tsis muaj qhov sib txawv ntawm cov txheej txheem ntawm tag nrho argon arc vuam thiab argon arc vuam.Tag nrho argon arc vuam yog tsim rau nyias-walled me-inch kav (feem ntau DN60 thiab hauv qab no, phab ntsa thickness 4 hli), lub hom phiaj yog los xyuas kom meej qhov zoo ntawm weld cag thiab cov tsos.

Thaum txoj kab uas hla ntawm cov yeeb nkab loj thiab cov phab ntsa tuab yog tuab, argon arc vuam yuav tsum tau siv los ua lub hauv paus thiab phau ntawv vuam los npog qhov chaw.Lub hom phiaj ntawm phau ntawv welding yog los xyuas kom meej qhov zoo ntawm cov yeeb nkab txoj kab uas hla loj thiab phau ntawv welding, thiab kev ua hauj lwm efficiency siab tshaj li argon arc vuam.qis dua argon arc vuam.

Cov txheej txheem argon arc vuam hauv qab vuam txheej txheem yog siv rau hauv vuam ntawm boiler dej phab ntsa, superheaters, economizers, thiab lwm yam. Qhov zoo ntawm cov pob qij txha yog zoo heev, thiab cov qib weld yog siab dua Class II tom qab kuaj radiographic.

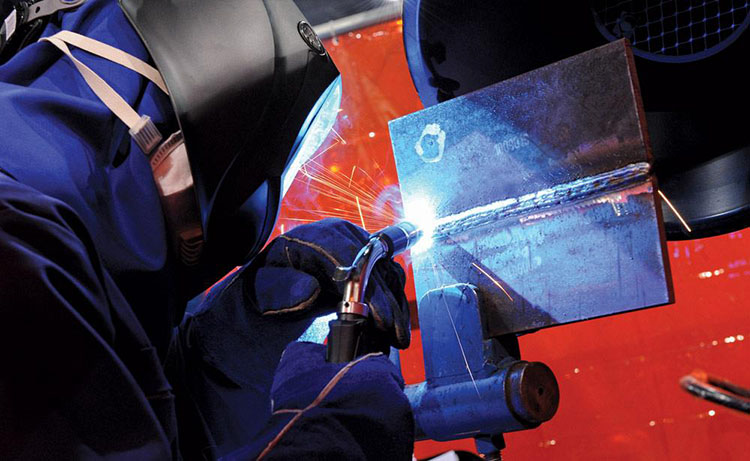

Qhov zoo ntawm argon arc vuam

(1) zoo zoo

Ntev npaum li qhov tsim nyog vuam hlau, cov txheej txheem vuam tsis zoo thiab kev tiv thaiv roj zoo raug xaiv, cov hauv paus hniav tuaj yeem nkag mus tau zoo, thiab kev nkag mus tau zoo ib yam, thiab qhov chaw yog du thiab huv.Tsis muaj qhov tsis xws luag xws li vuam pob, tsis tiav kev nkag mus, kev nyuaj siab, pores thiab slag inclusions uas yooj yim tshwm sim thaum lub sij hawm arc vuam nrog cov electrodes.

(2) High efficiency

Nyob rau hauv thawj txheej ntawm vuam ntawm cov kav dej, phau ntawv argon arc vuam yog nruam arc vuam.Cov electrode arc vuam yog tawg arc vuam, yog li phau ntawv argon arc vuam tuaj yeem ua rau kom muaj txiaj ntsig los ntawm 2 mus rau 4 zaug.Txij li thaum argon arc vuam tsis tsim vuam slag, tsis tas yuav ntxuav cov slag thiab kho cov hlaws vuam, thiab qhov ceev yuav nce sai dua.Nyob rau hauv lub thib ob txheej ntawm arc vuam npog nto, tus du thiab huv si argon arc vuam hauv qab txheej yog zoo heev rau lub arc vuam npog nto, uas muaj peev xwm xyuas kom meej zoo fusion ntawm cov khaubncaws sab nraud povtseg, tshwj xeeb tshaj yog nyob rau hauv lub vuam ntawm me me txoj kab uas hla kav, efficiency yog ntau. tseem ceeb.

(3) Yooj yim rau tus tswv

Lub vuam ntawm lub hauv paus vuam ntawm phau ntawv arc vuam yuav tsum tau ua los ntawm kev paub thiab txawj welders.Kev tuav argon arc vuam yog siv rau kev thim rov qab, thiab cov neeg ua haujlwm uas feem ntau koom nrog kev ua haujlwm vuam tuaj yeem ua tiav nws tom qab lub sijhawm luv luv ntawm kev xyaum.

(4) Me me deformation

Lub tshav kub-cuam tshuam cheeb tsam yog me dua thaum lub sij hawm argon arc vuam, yog li lub deformation ntawm cov welded sib koom yog me me thiab cov residual kev nyuaj siab kuj yog me me.

Kev taw qhia txog txheej txheem

(1) Vuam piv txwv

Lub economizer, evaporator tube bundle, dej phab ntsa thiab low-temperature superheater yog ua los ntawm No. 20 steel, thiab high-temperature superheater raj yog 12Cr1MoV.

(2) Kev npaj ua ntej vuam

Ua ntej vuam, lub qhov ncauj yeeb nkab yuav tsum tau beveled ntawm 30°, thiab cov xim hlau yuav tsum tau polished nyob rau hauv 15mm sab hauv thiab sab nraum cov yeeb nkab kawg.Qhov sib txawv ntawm cov yeeb nkab counterparts yog 1 ~ 3mm.Thaum qhov sib txawv tiag tiag yog qhov loj heev, nws yog qhov yuav tsum tau surfacing cov txheej txheem hloov ntawm sab ntawm cov yeeb nkab zawj ua ntej.Teeb tsa cov chaw nyob ib ntus cua thiab tswj xyuas cov cua ceev ntawm qhov chaw ua haujlwm vuam, vim tias cua ceev tshaj qhov ntau, thiab cov cua qhov tau yooj yim tsim.

(3) Kev ua haujlwm

Siv phau ntawv tungsten argon arc vuam tshuab, lub vuam tshuab nws tus kheej yog nruab nrog lub tshuab hluav taws xob arc ignition siab, thiab siv lub tshuab hluav taws xob ntau zaus.Arc extinguishing yog txawv ntawm electrode arc vuam.Yog hais tias lub arc yog extinguished sai heev, arc crater tawg yooj yim tshwm sim.Yog li ntawd, thaum lub sij hawm ua hauj lwm, lub molten pas dej ua ke yuav tsum tau coj mus rau lub ntug los yog lub thicker puag hlau, thiab ces maj mam shrink lub molten pas dej ua ke maj mam extinguish arc, thiab thaum kawg kaw lub arc.Kev tiv thaiv roj.

Rau No. 20 steel kav nrog phab ntsa tuab ntawm 3 ~ 4 hli, cov khoom ntim tuaj yeem yog TIGJ50 (rau 12Cr1MoV, 08CrMoV siv tau), txoj kab uas hla ntawm tungsten pas nrig yog 2 hli, qhov vuam tam sim no yog 75 ~ 100A, lub arc voltage yog 12 ~ 14V, thiab tus nqi ntws ntawm cov roj shielding yog 8 ~ 10L / min, hom fais fab mov yog DC zoo txuas.

Yog vim li cas vim li cas argon arc vuam siv tau dav heev yog vim muaj cov hauv qab no zoo.

1. Argon tiv thaiv tuaj yeem cais cov kev txom nyem, txo cov pa taws, txo cov pa taws, thiab dawb, muaj txiaj ntsig zoo welded pob qij txha;

2. Lub arc combustion ntawm argon arc vuam yog ruaj khov, lub tshav kub yog concentrated, lub arc kem kub yog siab, lub vuam ntau lawm efficiency yog siab, lub tshav kub-cuam tshuam cheeb tsam yog nqaim, thiab kev nyuaj siab, deformation thiab tawg nyiam ntawm welded qhov chaw me me;

3. Argon arc vuam yog qhib arc vuam, uas yooj yim rau kev khiav lag luam thiab kev soj ntsuam;

4. Cov electrode poob yog me me, qhov ntev arc yog yooj yim los tswj, thiab tsis muaj flux lossis txheej txheej thaum vuam, yog li nws yooj yim rau kev paub tshuab thiab automation;

5. Argon arc vuam tuaj yeem vuam yuav luag txhua cov hlau, tshwj xeeb tshaj yog qee cov hlau refractory thiab yooj yim oxidized hlau, xws li magnesium, titanium, molybdenum, zirconium, txhuas, thiab lwm yam thiab lawv cov alloys;

6. Nws tsis yog txwv los ntawm txoj hauj lwm ntawm lub vuam, thiab tuaj yeem welded hauv txhua txoj haujlwm.

Lub ntsiab tsis zoo:

1. Vim yog qhov loj ntawm qhov kub thiab txias ntawm argon arc vuam, lub workpiece feem ntau ua rau deformation, siab hardness, hlwv, hauv zos annealing, cracking, pinholes, hnav, khawb, undercuts, los yog tsis txaus lub zog sib txuas thiab kev ntxhov siab tom qab kho.kev puas tsuaj xws li kev puas tsuaj.Tshwj xeeb tshaj yog nyob rau hauv cov txheej txheem ntawm kev kho me me tsis xws luag ntawm peev castings, nws yog ib qho tseem ceeb ntawm qhov chaw.Nyob rau hauv lub tshav pob ntawm kev kho qhov tsis xws luag ntawm precision castings, txias vuam tshuab yuav siv tau es tsis txhob argon arc vuam.Vim tias cov cua sov me me ntawm cov tshuab vuam txias, qhov tsis zoo ntawm argon arc vuam yog qhov zoo dua, thiab kho cov teeb meem ntawm precision castings yog tsim rau.

2. Argon arc vuam yog teeb meem rau tib neeg lub cev ntau dua li electrode arc vuam.Tam sim no qhov ceev ntawm argon arc vuam yog siab, thiab lub teeb emissions kuj muaj zog.Cov hluav taws xob ultraviolet tsim los ntawm nws cov arc yog hais txog qhov zoo tib yam electrode arc vuam.5 mus rau 30 zaug, thiab infrared rays yog li ntawm 1 mus rau 1.5 npaug ntawm electrode arc vuam.Cov ntsiab lus ozone tsim thaum lub sijhawm vuam yog qhov siab.Yog li ntawd, sim xaiv qhov chaw uas muaj huab cua zoo rau kev tsim kho, txwv tsis pub nws yuav ua rau muaj kev puas tsuaj loj rau lub cev.

3. Rau cov hlau uas tsis tshua muaj melting point thiab evaporation yooj yim (xws li txhuas, tin, zinc), vuam yog qhov nyuaj dua.

Post lub sij hawm: Aug-16-2023