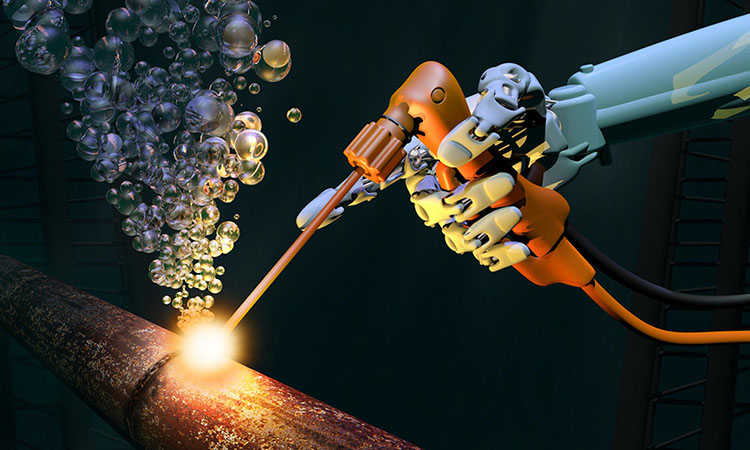

Muaj peb hom kev vuam hauv qab dej: txoj kev qhuav, txoj kev ntub dej thiab ib nrab txoj kev qhuav.

Qhuav vuam

Qhov no yog ib txoj hauv kev uas lub tshuab cua loj yog siv los npog cov vuam, thiab cov welder ua cov vuam hauv cov cua chamber.Txij li thaum lub vuam yog ua nyob rau hauv ib tug qhuav roj theem, nws muaj kev ruaj ntseg zoo dua.Thaum qhov tob tshaj qhov kev dhia dej ntawm huab cua, cov pa taws tau yooj yim tsim vim qhov nce ntawm cov pa oxygen hauv zos hauv huab cua ib puag ncig.Yog li ntawd, yuav tsum tau siv cov roj inert los yog semi-inert nyob rau hauv cov roj chamber.Thaum lub sij hawm vuam qhuav, welders yuav tsum hnav tshwj xeeb fireproof thiab kub resistant khaub ncaws.Piv nrog rau ntub thiab qhuav vuam ib nrab, qhuav vuam muaj qhov zoo tshaj plaws kev nyab xeeb, tab sis nws siv yog heev txwv thiab nws daim ntawv thov tsis yog universal.

ib nrab qhuav vuam

Txoj kev qhuav hauv zos yog ib txoj hauv kev hauv qab dej welding uas tus welder ua welding hauv dej thiab ua kom cov dej ntws tawm ntawm qhov chaw vuam, thiab nws cov kev ntsuas kev nyab xeeb zoo ib yam li cov txheej txheem ntub dej.

Txij li thaum qhov chaw qhuav txoj kev tseem nyob rau hauv kev tshawb fawb, nws txoj kev siv tseem tsis tau nthuav dav.

Wet vuam

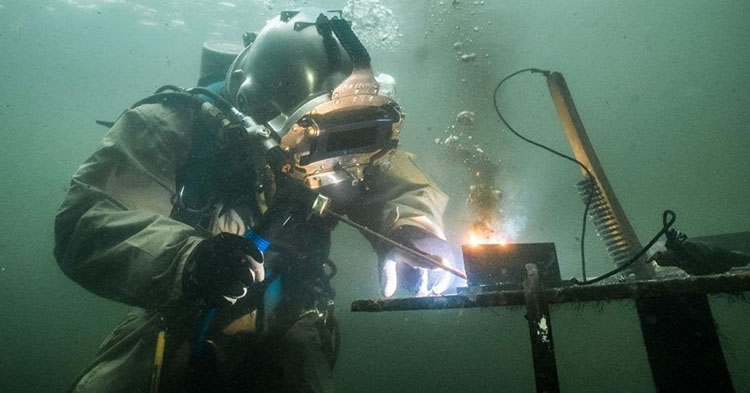

Wet welding yog ib txoj kev vuam hauv qab dej uas tus welder ncaj qha welds hauv qab dej es tsis txhob tso dej tawm ntawm qhov chaw vuam.

Arc hlawv hauv qab dej zoo ib yam li submerged arc vuam, thiab nws kub hnyiab hauv huab cua npuas.Thaum cov electrode hlawv, cov txheej ntawm cov electrode tsim ib lub tes tsho uas stabilizes huab cua npuas thiab yog li stabilizes lub arc.Txhawm rau ua kom cov hluav taws xob kub hnyiab hauv qab dej, nws yog ib qho tsim nyog yuav tsum tau coated ib co thickness ntawm txheej ntawm lub electrode core thiab impregnate nws nrog paraffin los yog lwm yam dej tsis haum tshuaj kom lub electrode waterproof.Npuas yog hydrogen, oxygen, dej vapor thiab npuas tsim los ntawm combustion ntawm electrode coatings;Lwm cov oxides uas ua los ntawm cov pa taws turbid.Txhawm rau kov yeej qhov nyuaj ntawm arc ignition thiab arc stabilization tshwm sim los ntawm dej txias thiab siab, lub arc ignition voltage yog siab tshaj qhov nyob rau hauv cov huab cua, thiab nws tam sim no yog 15% mus rau 20% loj dua cov vuam tam sim no nyob rau hauv cov huab cua.

Piv nrog rau qhov qhuav thiab ib nrab qhuav welding, underwater wet welding muaj feem ntau siv, tab sis kev nyab xeeb yog qhov phem tshaj.Vim yog cov dej conductivity, kev tiv thaiv hluav taws xob poob siab yog ib qho kev txhawj xeeb tseem ceeb ntawm kev ntub dej vuam.

Kev ntub dej hauv qab vuam yog ua ncaj qha rau hauv cov dej sib sib zog nqus, uas yog, nyob rau hauv cov xwm txheej uas tsis muaj qhov cuam tshuam ntawm qhov vuam thiab dej.Lub vuam tsis yog tsuas yog cuam tshuam los ntawm cov dej ambient siab, tab sis kuj ua kom txias los ntawm cov dej nyob ib puag ncig.

Txawm hais tias ntub dej hauv qab vuam yog yooj yim thiab hloov tau, thiab xav tau cov cuab yeej siv yooj yim thiab cov xwm txheej, vim qhov txias txias ntawm vuam arc, molten pas dej ua ke, electrode thiab vuam hlau los ntawm dej, qhov ruaj khov ntawm lub arc raug rhuav tshem, thiab cov duab vuam tsis zoo. .Lub hardened cheeb tsam yog tsim nyob rau hauv lub vuam tshav kub-tshwj xeeb cheeb tsam, thiab ib tug loj npaum li cas ntawm hydrogen yog intruded rau hauv arc kem thiab molten pas dej ua ke thaum lub sij hawm vuam txheej txheem, uas tej zaum yuav ua rau tsis xws luag xws li vuam tawg thiab pores.Yog li ntawd, ntub dej hauv qab vuam feem ntau yog siv rau hauv cov dej ntiav ntiav nrog cov dej hiav txwv zoo thiab vuam ntawm cov khoom uas tsis tas yuav tsum muaj kev ntxhov siab.

Qhov ib puag ncig hauv qab dej ua rau cov txheej txheem vuam hauv qab dej ntau nyuaj dua li cov txheej txheem vuam av.Ntxiv nrog rau kev siv thev naus laus zis, nws kuj tseem muaj ntau yam xws li kev ua haujlwm dhia dej.Cov yam ntxwv ntawm underwater welding yog:

1. Tsis tshua pom kev.Kev nqus, kev xav thiab refraction ntawm lub teeb los ntawm dej yog ntau zog dua li ntawm huab cua.Yog li ntawd, lub teeb tsis muaj zog sai sai thaum nws nthuav tawm hauv dej.Tsis tas li ntawd, ntau cov npuas thiab cov pa luam yeeb yog tsim nyob ib ncig ntawm lub arc thaum lub sij hawm vuam, ua rau lub underwater arc qis heev nyob rau hauv visibility.Underwater welding yog nqa tawm nyob rau hauv av nkos seabed thiab hiav txwv cheeb tsam nrog xuab zeb thiab av nkos, thiab visibility nyob rau hauv dej yog txawm phem.

2. Lub vuam seam muaj cov ntsiab lus hydrogen siab, thiab hydrogen yog tus yeeb ncuab ntawm vuam.Yog hais tias cov ntsiab lus hydrogen nyob rau hauv vuam ntau tshaj qhov tso cai, nws yog ib qho yooj yim los ua kom tawg thiab txawm ua rau kev puas tsuaj.Lub underwater arc yuav ua rau thermal decomposition ntawm cov dej nyob ib puag ncig, ua rau muaj kev nce hauv hydrogen yaj hauv qhov vuam.Qhov tsis zoo ntawm cov pob qij txha welded ntawm underwater electrode arc vuam yog sib cais los ntawm cov ntsiab lus siab hydrogen.

3. Qhov txias txias yog ceev.Thaum vuam underwater, thermal conductivity ntawm seawater yog siab, uas yog hais txog 20 npaug ntawm huab cua.Yog hais tias txoj kev ntub dej los yog hauv zos txoj kev siv rau hauv qab dej welding, lub workpiece yuav tsum tau welded yog ncaj qha mus rau hauv dej, thiab quenching nyhuv ntawm cov dej ntawm lub weld yog pom tseeb, thiab nws yog ib qho yooj yim los tsim ib tug high-hardness hardened qauv.Yog li ntawd, cov nyhuv txias tsuas tuaj yeem zam tau thaum siv vuam qhuav.

4. Kev cuam tshuam ntawm lub siab, thaum lub siab nce, lub arc kem yuav thinner, qhov dav ntawm lub weld hlaws yuav nqaim, qhov siab ntawm weld seam nce, thiab qhov ceev ntawm cov conductive nruab nrab nce, uas ua rau kom qhov nyuaj ntawm ionization. , arc voltage nce raws li, thiab arc stability Txo, nce txaws thiab pa taws.

5. Kev ua haujlwm tsis tu ncua yog qhov nyuaj rau kev paub.Vim muaj kev cuam tshuam thiab kev txwv ntawm ib puag ncig hauv qab dej, hauv ntau qhov xwm txheej, txoj kev vuam rau ib ntu thiab nres rau ib ntu yuav tsum tau saws, uas ua rau cov welds tsis tu ncua.

Kev nyab xeeb ntawm ntub dej hauv qab vuam yog qhov phem dua li ntawm thaj av.Cov kev ntsuas kev nyab xeeb tseem ceeb yog:

Cov tam sim no ncaj qha yuav tsum tau siv rau kev vuam hauv qab dej, thiab kev hloov tam sim no raug txwv.Qhov tsis muaj qhov hluav taws xob feem ntau yog 50-80V.Tswj cov khoom siv hluav taws xob hauv kev sib cuag ncaj qha nrog cov welders dhia dej yuav tsum siv cov hloov hluav taws xob cais tawm thiab tiv thaiv los ntawm overload.Ua ntej dhia welders pib ua haujlwm lossis thaum lub sijhawm hloov cov electrodes, lawv yuav tsum ceeb toom rau cov neeg ua haujlwm hauv av kom txiav tawm lub voj voog.Kev dhia dej welding yuav tsum hnav khaub ncaws tiv thaiv tshwj xeeb thiab hnab looj tes tshwj xeeb.Thaum lub sij hawm arc ignition thiab arc txuas ntxiv, tes yuav tsum tsis txhob kov cov workpieces, cables, welding rods, thiab lwm yam. Thaum welding ntawm ib tug nyob qauv, tam sim no ntawm cov qauv yuav tsum raug txiav tawm ua ntej.Thaum lub sijhawm ua haujlwm hauv qab dej, kev tiv thaiv kev ua haujlwm huv, tshwj xeeb tshaj yog kev tiv thaiv hauv nroog thiab kev tiv thaiv kub hnyiab yuav tsum tau muab.Tsis tu ncua xyuas qhov kev ua tau zoo ntawm rwb thaiv tsev thiab kev ua haujlwm tsis zoo ntawm cov khoom siv hauv qab dej welding, vuam tongs, cables, thiab lwm yam.

Post lub sij hawm: Lub Xya hli ntuj-12-2023