Cov txheej txheem submerged arc vuam yog qhov kev xaiv zoo tshaj plaws hauv cov ntawv thov tseem ceeb ntawm cov kav dej, cov hlab ntsha siab thiab cov tso tsheb hlau luam, taug qab kev tsim khoom thiab kev tsim kho loj.Nws muaj qhov yooj yim tshaj plaws ib qho hlau daim ntawv, ob chav hlau qauv, series ob chav hlau qauv thiab ntau hlau qauv.

Lub submerged arc vuam txheej txheem tuaj yeem muaj txiaj ntsig zoo rau cov neeg siv khoom siv hauv ntau qhov kev siv vuam, los ntawm kev tsim khoom ntau ntxiv rau kev txhim kho kev ua haujlwm kom zoo ib yam thiab ntau dua.Hlau fabrication nroj tsuag uas tab tom xav txog kev hloov pauv rau submerged arc vuam txheej txheem yuav tsum xav txog ntau yam txiaj ntsig uas tuaj yeem tau txais los ntawm cov txheej txheem no.

Kev paub yooj yim ntawm submerged arc vuam

Lub submerged arc vuam txheej txheem yog tsim rau hnyav industrial daim ntawv thov ntawm piping, siab hlab ntsha thiab tso tsheb hlau luam, locomotive siv, hnyav siv / excavation.Qhov zoo tshaj plaws rau kev lag luam uas xav tau cov khoom lag luam siab, tshwj xeeb tshaj yog cov uas muaj kev sib txuas ntawm cov ntaub ntawv tuab heev, uas tuaj yeem tau txais txiaj ntsig zoo los ntawm submerged arc vuam txheej txheem.

Nws qhov kev tso nyiaj siab thiab kev mus ncig ceev tuaj yeem ua rau muaj kev cuam tshuam loj rau cov neeg ua haujlwm tsim khoom, kev ua haujlwm thiab cov nqi tsim khoom, uas yog ib qho tseem ceeb ntawm cov txheej txheem submerged arc vuam.

Cov txiaj ntsig ntxiv muaj xws li: welds nrog cov tshuaj lom neeg zoo heev thiab cov khoom siv kho tshuab, qhov pom qhov tsawg tsawg thiab qhov vuam tsis zoo, kev ua haujlwm zoo dua qub, thiab zoo weld zoo thiab cov kab ntiv taw.

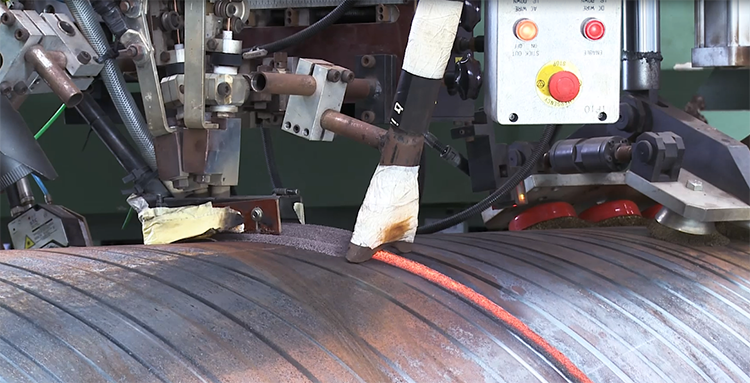

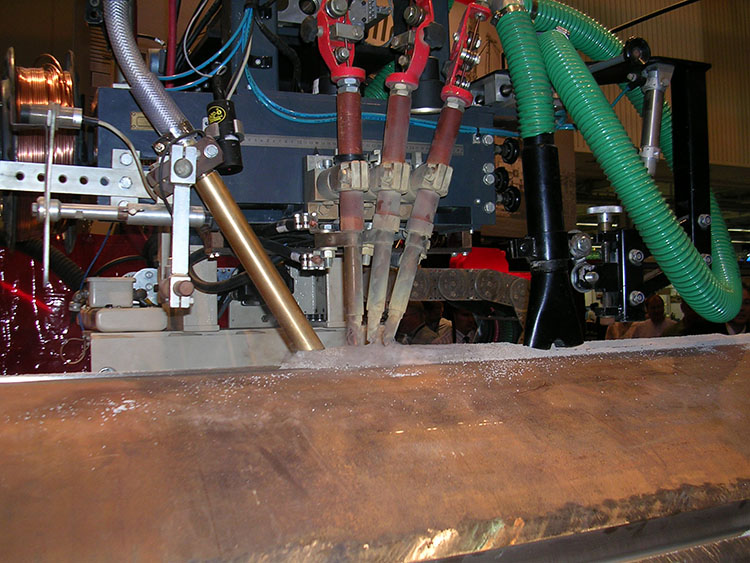

Submerged arc welding yog ib txoj hlua pub mis uas siv cov kua nplaum los cais cov arc ntawm huab cua.Raws li lub npe qhia, lub arc yog faus rau hauv lub flux, lub ntsiab lus hais tias thaum lub parameters teem, lub arc yog tsis pom nrog cov ntws ntawm ib tug tom ntej txheej ntawm flux.

Cov hlau tsis tu ncua pub los ntawm ib lub teeb txav raws qhov weld.Arc cua sov melts ib feem ntawm cov hlau, ib feem ntawm cov flux thiab cov khoom siv hauv paus los ua ib lub pas dej molten, uas condenses rau daim ntawv weld npog nrog ib txheej ntawm vuam slag.

Qhov tuab ntawm cov khoom siv vuam yog 1/16 "-3/4", uas tuaj yeem yog 100% nkag mus rau vuam los ntawm ib qho kev sib txuas, yog tias cov phab ntsa tuab tsis txwv, nws tuaj yeem ua tau ntau qhov vuam, thiab ua kom tsim nyog. pre-kev kho mob xaiv ntawm weld, thiab xaiv qhov tsim nyog hlau flux ua ke.

Flux thiab hlau xaiv

Xaiv txoj cai flux thiab xaim rau ib qho tshwj xeeb submerged arc vuam txheej txheem yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig zoo tshaj plaws nrog cov txheej txheem ntawd.Txawm hais tias submerged arc vuam txheej txheem ib leeg yog qhov ua tau zoo, kev tsim khoom thiab kev ua haujlwm tuaj yeem nce ntxiv txawm tias raws li cov xaim thiab flux siv.

Lub flux tsis tsuas yog tiv thaiv lub pas dej ua ke, tab sis kuj tseem txhawb kev txhim kho cov khoom siv kho tshuab thiab kev tsim khoom ntawm weld.Lub formulation ntawm flux yog ib qho kev cuam tshuam loj rau cov yam ntxwv no, cuam tshuam rau lub peev xwm nqa tam sim no thiab slag tso tawm.Lub peev xwm nqa tam sim no txhais tau hais tias qhov ua tau zoo tshaj plaws ntawm kev tso nyiaj thiab cov khoom siv vuam zoo tuaj yeem tau txais.

Lub slag tso tawm ntawm ib qho flux cuam tshuam rau kev xaiv flux vim tias qee qhov fluxes zoo dua rau qee qhov kev tsim vuam dua li lwm tus.

Flux xaiv xaiv rau submerged arc vuam muaj xws li active thiab nruab nrab hom vuam.Ib qho tseem ceeb sib txawv yog tias cov nquag flux hloov chemistry ntawm lub vuam, thaum lub nruab nrab flux tsis.

Active flux yog tus cwj pwm los ntawm kev suav nrog silicon thiab manganese.Cov ntsiab lus no pab tswj cov weld tensile lub zog ntawm cov khoom siv hluav taws xob siab, pab weld nyob twj ywm du ntawm kev mus los nrawm thiab muab cov slag tso tawm zoo.

Zuag qhia tag nrho, nquag flux tuaj yeem pab txo qhov kev pheej hmoo ntawm cov vuam tsis zoo, nrog rau cov khoom kim heev tom qab vuam thiab rov ua haujlwm dua.

Nco ntsoov, txawm li cas los xij, qhov active flux feem ntau yog qhov zoo tshaj plaws rau ib leeg lossis ob zaug dhau los vuam.Neutral fluxes yog qhov zoo dua rau cov welds loj loj vim tias lawv pab kom tsis txhob tsim cov nkig, tawg-rhiab welds.

Muaj ntau txoj kev xaiv xaim rau submerged arc vuam, txhua qhov zoo thiab qhov tsis zoo.Qee cov xov hlau yog tsim los rau vuam ntawm cov khoom siv hluav taws xob ntau dua, thaum lwm tus yog tsim tshwj xeeb kom muaj cov hlau nplaum uas pab cov flux ntxuav lub vuam.

Nco ntsoov tias cov khoom siv tshuaj lom neeg ntawm cov hlau thiab cov khoom siv hluav taws xob sib txuas tuaj yeem cuam tshuam rau cov khoom siv hluav taws xob ntawm cov vuam.Productivity kuj tuaj yeem txhim kho tau zoo los ntawm kev sau cov hlau xaiv.

Piv txwv li, siv cov hlau-cored hlau nrog submerged arc vuam txheej txheem tuaj yeem ua rau kom cov khoom siv tau zoo dua los ntawm 15 mus rau 30 feem pua piv rau kev siv cov khoom siv hlau, thaum tseem muab qhov dav dua, qhov tob tob tob.

Vim nws txoj kev mus los ceev, cov hlau cored hlau kuj txo cov cua sov tawm kom txo tau qhov kev pheej hmoo ntawm vuam distortion thiab hlawv tawm.Thaum muaj kev tsis ntseeg, sab laj nrog lub chaw tsim khoom siv hlau los txiav txim seb qhov sib txuas ntawm cov hlau thiab flux yog qhov zoo tshaj plaws rau ib daim ntawv thov.

Post lub sij hawm: Jun-27-2023