Thaum lub sij hawm fusion welding, nyob rau hauv qhov kev txiav txim ntawm lub vuam kub qhov chaw, cov kua hlau ib feem nrog ib tug tej yam geometric duab tsim nyob rau hauv lub welment los ntawm molten electrode hlau thiab ib nrab molten puag hlau yog lub molten pas dej ua ke.Tom qab txias, nws dhau los ua vuam, yog li qhov kub ntawm lub pas dej molten ncaj qha cuam tshuam rau vuam zoo.

Yog tias qhov kub ntawm lub pas dej molten yog siab, lub pas dej molten loj, thiab cov hlau molten muaj fluidity zoo, qhov fusion zone yog ib qho yooj yim rau fuse;tab sis thaum qhov kub thiab txias dhau lawm, cov hlau molten yog ib qho yooj yim rau drip, thiab sab nraub qaum ntawm ib sab welding thiab ob sab sib sau yog ib qho yooj yim los hlawv, daim ntawv weld pob, thiab cov duab.Nws yog ib qho nyuaj rau kev tswj, thiab cov plasticity ntawm kev sib koom ua ke yog txo, thiab kev sib koom ua ke yooj yim tawg;Thaum qhov kub ntawm lub pas dej molten tsawg, lub pas dej molten me me, cov hlau molten yog xim dub, thiab cov fluidity tsis zoo.Nws yog ib qho yooj yim los tsim cov teeb meem xws li kev nkag mus tsis tiav, tsis muaj fusion, thiab slag suav nrog.

Yog li ntawd, zoo tswj qhov kub ntawm lub pas dej molten yog ib qho tseem ceeb heev kom ntseeg tau tias cov nyhuv vuam thiab qhov zoo ntawm cov khoom tiav.

Daim duab 1 Tianqiao vuam

Qhov kub ntawm lub pas dej molten yog ze ze rau lub vuam tam sim no, txoj kab uas hla ntawm lub electrode, txoj kev thauj mus los, lub kaum sab xis ntawm lub electrode, thiab lub sij hawm arc hlawv.Cov kev ntsuas hauv qab no yog coj los tswj qhov kub ntawm lub pas dej molten raws li qhov cuam tshuam.

1. Vuam tam sim no thiab electrode txoj kab uas hla

Ob qho no yog qhov tseem ceeb rau kev vuam, thiab ob qho tib si kuj muaj kev sib cais tsis sib xws.Thaum lub sij hawm fusion welding, qhov tam sim no ntws rov qab los ntawm qhov vuam yog hu ua vuam tam sim no.Txoj kab uas hla ntawm lub electrode yog hais txog qhov sib txawv ntawm qhov loj ntawm cov pas nrig hlau.Hauv cov ntsiab lus yooj yim, seb lub vuam pas nrig puas tuaj yeem ua kom zoo yog txiav txim siab los ntawm qhov tam sim no dhau mus.

Yog tias qhov tam sim no me me dhau lawm, nws nyuaj rau pib lub arc, lub electrode yog ib qho yooj yim rau lo rau lub vuam, cov nplai ntses yog tuab, thiab ob sab tsis fused;Yog tias qhov tam sim no loj dhau, cov txaws thiab cov pa luam yeeb thaum lub sij hawm vuam yuav loj, cov electrode yuav liab, thiab qhov chaw ntawm lub pas dej molten yuav ci heev.Nws yog ib qho yooj yim mus hlawv thiab undercut;Thaum qhov tam sim no tsim nyog, nws yog ib qho yooj yim rau ignite thiab lub arc yog ruaj khov, cov txaws me me, lub suab tsis sib xws tuaj yeem hnov, ob sab ntawm vuam seam smoothly hloov mus rau cov khoom siv hauv paus, cov nplai ntses ntses yog heev. nyias, thiab vuam slag yog yooj yim Knock tawm.Hais txog nws daim ntawv thov, muaj kev sib raug zoo.

1.1 Xaiv qhov vuam tam sim no thiab electrode txoj kab uas hla raws li qhov chaw ntawm qhov vuam

Nyob rau hauv txoj haujlwm ntsug, kab rov tav thiab ntsug, qhov tam sim no sib npaug me dua li cov vuam vuam, thiab tam sim no feem ntau yuav tsum yog li 10% me dua li ntawm cov vuam vuam.

Ib yam li ntawd, nyob rau hauv txoj hauj lwm ntsug, kab rov tav, thiab upright, txoj kab uas hla ntawm lub electrode feem ntau yog me dua li ntawm lub tiaj vuam.Piv txwv li, nyob rau hauv lub tiaj welding ntawm lub tiaj phaj loj dua 12 hli, 5.0mm electrode feem ntau yog siv., Thiab yuav luag tsis muaj electrode nrog ib txoj kab uas hla ntawm 5.0mm nyob rau hauv txoj hauj lwm ntsug, kab rov tav thiab upright.

1.2 welding tam sim no thiab electrode txoj kab uas hla yog xaiv raws li qhov vuam theem ntawm vuam.

Piv txwv li, rau 12 hli tiaj phaj pob tw pob qij txha, 3.2 hliTianqiao electrodesfeem ntau yog siv rau hauv qab txheej ntawm lub tiaj vuam, thiab vuam tam sim no yog 90-110A, thiab 4.0mmTianqiao electrodestuaj yeem siv rau kev sau thiab npog txheej, thiab vuam tam sim no yog 160-175A.

Yog li ntawd, kev xaiv tsim nyog ntawm cov vuam tam sim no thiab txoj kab uas hla ntawm cov electrode tuaj yeem tswj tau qhov kub ntawm lub pas dej molten, uas yog lub hauv paus rau kev tsim cov vuam zoo.Yog tias qhov vuam tam sim no me me dhau, qhov kub ntawm lub pas dej welding tsawg dhau, ua rau lub arc tsis ruaj khov, thiab cov khoom ua haujlwm yuav tsis raug welded.Yog tias qhov vuam tam sim no siab dhau lawm thiab qhov kub ntawm lub pas dej molten siab dhau lawm, nws yuav ua rau tawg loj thiab ntws ntawm cov hlau molten, thiab txawm hlawv los ntawm lub workpiece los ua cov hlaws vuam.

Kev sib raug zoo ntawm cov vuam tam sim no thiab txoj kab uas hla ntawm electrode yog teev hauv qab no.Koj tuaj yeem xaiv qhov tsim nyog raws li koj tus kheej kev paub lossis tus cwj pwm.Koj tsis tas yuav txiav txim siab tib yam tsis zoo ib yam li lwm tus, tsuav yog koj xav tias nws tsim nyog thiab xyuas kom muaj kev sib txuas zoo.

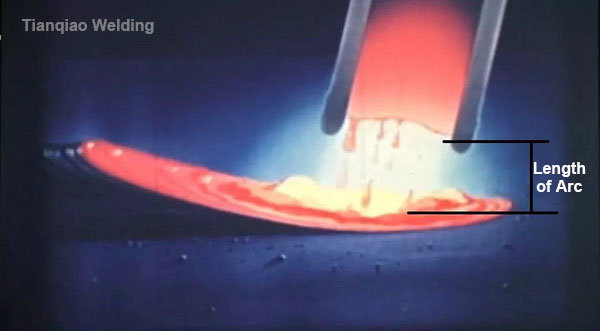

2. Kev thauj mus los ntawm vuam pas nrig

Covvuam rodyog pub nyob rau hauv cov kev taw qhia ntawm lub molten pas dej ua ke raws axis.Tom qab lub vuam pas nrig yog melted, qhov ntev ntawm lub arc tuaj yeem khaws cia.Yog li ntawd, qhov ceev ntawm lub vuam pas nrig nyob rau hauv cov kev taw qhia ntawm lub molten pas dej ua ke yuav tsum tau sib npaug zos rau melting ceev ntawm lub vuam pas nrig.

Yog tias qhov kev pub mis ceev ntawm cov electrode qis dua qhov ceev ntawm cov electrode melting, qhov ntev ntawm lub arc yuav maj mam nce, ua rau arc cuam tshuam;Yog hais tias qhov ceev ntawm lub electrode yog ceev heev, qhov ntev ntawm lub arc yuav luv luv, thiab qhov kawg ntawm electrode yuav luv luv nyob rau hauv kev sib cuag nrog lub weldment.Extinguish lub arc.

Daim duab 2 Tianqiao vuam

3. Lub kaum sab xis ntawm kev xa khoom thiab kev pub mis

Thaum lub sij hawm vuam, lub kaum sab xis ntawm lub electrode yuav tsum hloov nrog txoj hauj lwm vuam, thiab ib txwm ua kom qhov kub thiab txias ntawm lub pas dej molten ntawm ob sab ntawm lub blunt ntug tsim nyog.Yog tias qhov kub thiab txias heev, nws yuav ua rau kub hnyiab, thiab yog tias nws qis dhau, nws yuav ua rau qhov tshwm sim ntawm kev nkag mus tsis txaus thiab fusion.Thaum lub kaum sab xis ntawm lub electrode thiab vuam kev taw qhia yog 90 degrees, lub arc yog concentrated thiab qhov kub ntawm lub pas dej molten yog siab;

Yog tias lub kaum sab xis me dua, lub arc yuav tawg thiab qhov kub ntawm lub pas dej molten yuav qis dua.Piv txwv li, yog tias cov txheej hauv qab ntawm 12 hli ca vuam foob, yog lub vuam pas nrig lub kaum sab xis yog 50-70 degrees, qhov kub ntawm lub pas dej molten yuav txo qis rau lub sijhawm no, thiab qhov tshwm sim ntawm vuam hlaws lossis nce rau sab nraub qaum. yog zam.Rau lwm qhov piv txwv, tom qab hloov cov vuam pas nrig hauv qab ntawm 12 hli phaj ntsug vuam foob, peb siv lub kaum sab xis 90-95 degree vuam pas nrig thaum thauj cov vuam pas nrig, kom qhov kub ntawm lub pas dej molten tuaj yeem nce sai, Lub qhov molten tuaj yeem qhib tau yooj yim, thiab sab nraub qaum yog tsim kom tiaj tus, uas tuaj yeem tswj tau zoo.Qhov tshwm sim uas qhov sib koom taw tes yog concave.

Yog hais tias lub electrode pub txoj hauj lwm tsis txaus, nws yuav ua rau tsis txaus nkag los yog zawj clamping.Vim hais tias lub arc yog dispersed nyob rau lub sij hawm no, lub melting kub ntawm blunt ntug ntawm lub hauv paus cov ntaub ntawv tsis txaus, uas ua rau lub unfusion ntawm lub hauv paus khoom nyob rau hauv qab;Yog tias koj xav kom tag nrho cov hlau yaj, koj yuav tsum ua kom lub sij hawm melting.Vuam, multi-layer superposition ntawm molten pas dej ua ke yuav tsim slag inclusion phenomenon.

Txoj kev raug yog txhawm rau txuas lub vuam pas nrig rau hauv qhov zawj ntawm ntug qhov zawj ntawm lub kaum sab xis ntawm 75 degrees, ua kom cov khoom siv zawv zawg kom yaj thiab viav vias ntawm ob sab, txhua qhov kev txiav txim yuav siv li 1 vib nas this, kom deb li deb thawj lub pas dej molten yog tsim, thiab ces nkag mus rau tom ntej Lub tsim ntawm ib tug molten pas dej ua ke.Lub sijhawm no, lub sijhawm melting ntawm txhua lub pas dej molten yog luv luv thiab qhov hnyav yog lub teeb, thiab nws tsis tsim nyog ua rau poob, thiab vuam pob yuav tsis tsim.Lub groove ntiav kuj yog conducive rau vuam ntawm lub hau npog.

Lub pas dej tom kawg molten npog 2/3 ntawm qhov dhau los.Txhua lub pas dej molten yog nyias, thiab qhov kawg ua rau cov nyhuv tom qab cua sov ua rau yav dhau los, kom ntseeg tau tias cov pa roj hauv lub pas dej molten muaj sijhawm txaus los hla thiab tiv thaiv nws los ntawm kev tsim tawm.Stomata.

Daim duab 3 Tianqiao vuam

4. Arc hlawv lub sijhawm

Nyob rau hauv kev xyaum qhia ntawm kab rov tav thiab ntsug tsau vuam ntawm 57 × 3.5 kav, arc-breaking txoj kev yog siv rau vuam.Thaum pib vuam, qhov kub ntawm lub hauv paus hlau yog tsawg.Yog hais tias lub vuam pas nrig tsis muab tso rau ntawm ntug ntawm qhov zawj, cov hlau molten yuav sai sai thim rov qab thiab tsim cov undercuts.Lub weld tsim kuj yuav siab thiab nqaim, uas yuav tsis ua tiav cov nyhuv ntawm ntau smoothness, thiab nws yog ib qho yooj yim Lub resulting nto tsis fused.

Kev soj ntsuam los ntawm cov duab ntawm lub pas dej molten, yog tias nws nyob rau hauv cov duab ntawm ib tug poob, lub welded zoo yog twv yuav raug hu tsis zoo, thiab vuam hlaws yuav tshwm sim.Yog li ntawd, lub vuam taw tes yuav tsum tau tag nrho preheated los ntawm cov nyiaj siv ua haujlwm vuam.Lub kaum sab xis ntawm cov electrode thiab cov yeeb nkab yog 75 degrees.Tom qab lub arc yog ignited, lub arc yog stretched rau preheating.Tom qab thawj poob ntawm cov hlau molten ntawm lub taub hau electrode ntog, cov electrode raug xa mus rau hauv.

Qhov kub ntawm lub pas dej molten nyob rau lub sij hawm no yuav tsum xyuas kom meej tias qhov loj ntawm lub pas dej molten yog qhov zawj dav ntxiv li ntawm 1 hli, kom cov khoom siv hauv paus tuaj yeem ua tiav rau hauv cov tee los ua ib qho kev sib txuas.

Hauv kev ua haujlwm vuam tiag tiag, nws yog ib qho tsim nyog yuav tsum tau kawm saib xyuas cov kev hloov pauv ntawm qhov kub thiab txias ntawm lub pas dej molten thiab kom paub txog cov txheej txheem ntawm kev tswj qhov kub ntawm lub pas dej molten, uas yog lub hauv paus rau kev kawm vuam tshuab.Nws yog ib qho tsim nyog yuav tsum tau txiav txim siab lub vuam pas nrig lub kaum sab xis, qhov chaw pub mis thiab lub sijhawm yaj raws li lub pas dej molten ntawm txhua ntu, ceev nrooj tuav lub tshuab ua haujlwm ntawm ntau qhov tseem ceeb, thiab tom qab lub sijhawm ntawm kev cob qhia tiag tiag, qib kev kawm yuav txhim kho. sai heev, thiab qhov tshwm sim ntawm ntau yam vuam defects Qhov tseem ceeb txo qis, txhim kho lub zog muaj peev xwm nyob rau hauv txoj kev siv vuam, uas yog conducive rau kev txhim kho vuam technology nyob rau hauv lub neej yav tom ntej.

Post lub sij hawm: Lub Xya hli ntuj-15-2021