Lub zog ntawm brazing tuaj yeem yog cov tshuaj tiv thaiv hluav taws xob lossis hluav taws xob tsis ncaj qha.Nws siv cov hlau uas muaj cov ntsiab lus melting qis dua li cov khoom siv los ua welded raws li cov khoom siv.Tom qab cua sov, lub solder melts, thiab cov capillary nkaus thawb lub solder rau hauv qhov sib txawv ntawm qhov sib cuag ntawm qhov sib koom ua ke kom ntub dej ntawm cov hlau kom welded kom cov kua theem thiab cov khoom theem sib cais.Interdiffusion ntawm cov theem los ua ib qho kev sib koom ua ke.Yog li ntawd, brazing yog ib qho khoom-theem thiab kua-theem vuam txoj kev.

1. Cov yam ntxwv thiab daim ntawv thov ntawm brazing

Brazing siv ib qho alloy nrog lub melting point qis dua li ntawm lub hauv paus hlau li lub solder.Thaum rhuab, lub solder melts thiab sau thiab tseem nyob rau hauv qhov sib koom ua ke sib txawv los ntawm wetting thiab capillary kev txiav txim, thaum lub hauv paus hlau yog nyob rau hauv ib tug ruaj khov lub xeev, cia siab rau cov kua solder thiab cov khoom hauv paus Interdiffusion ntawm cov ntaub ntawv ua ib tug brazed sib koom.Brazing tsis tshua muaj txiaj ntsig rau lub cev thiab tshuaj lom neeg ntawm lub hauv paus hlau, tsis tshua muaj vuam kev nyuaj siab thiab deformation, tuaj yeem vuam cov hlau tsis sib xws nrog cov khoom sib txawv loj, tuaj yeem ua tiav ntau yam welds tib lub sijhawm, qhov zoo ntawm qhov sib koom ua ke zoo nkauj thiab huv si, cov cuab yeej siv tau yooj yim, thiab cov peev txheej tsim khoom me me.Txawm li cas los xij, lub brazed sib koom ua ke tsis muaj zog thiab tsis muaj cua sov ua haujlwm.

Daim ntaub ntawv: Carbide tej cuab yeej, drilling khoom, tsheb kauj vab ncej, tshav kub exchangers, conduits thiab ntau ntim, thiab lwm yam.;nyob rau hauv kev tsim cov microwave waveguides, electron tubes thiab electronics nqus tsev vacuum, brazing yog tsuas yog ib qho kev sib txuas txoj kev.

2.Brazing hlau thiab flux

Brazing muab tub lim hlau yog cov hlau muab tub lim uas ua rau lub taub hau brazing, thiab qhov zoo ntawm lub taub hau brazing yog nyob ntawm cov hlau muab tub lim mus rau qhov loj.Cov hlau muab tub lim yuav tsum muaj qhov tsim nyog melting point, zoo wettability thiab caulking muaj peev xwm, yuav tsum tau diffused nrog lub hauv paus hlau, thiab yuav tsum muaj tej yam khoom thiab lub cev thiab tshuaj zog kom tau raws li qhov yuav tsum tau ntawm kev sib koom tes.Raws li qhov sib txawv melting point ntawm brazing muab tub lim hlau, brazing tuaj yeem muab faib ua ob pawg: mos brazing thiab tawv brazing.

(1) Mos brazing.Brazing nrog lub melting point hauv qab 450 ° C yog hu ua mos brazing, thiab feem ntau siv brazing muab tub lim hlau yog tin lead brazing, uas muaj zoo wettability thiab hluav taws xob conductivity thiab yog dav siv nyob rau hauv cov khoom siv hluav taws xob, lub cev muaj zog thiab qhov chaw pib.Lub zog ntawm kev sib koom tes brazed feem ntau yog 60 ~ 140MPa.

(2) Brazing.Brazing nrog cov ntsiab lus melting siab tshaj 450 ° C yog hu ua brazing, thiab cov khoom siv sib txuas yog tooj dag thiab nyiaj hauv cov khoom siv brazing.Kev sib koom ua ke nrog cov nyiaj hauv lub hauv paus muab tub lim hlau muaj lub zog siab, hluav taws xob conductivity thiab corrosion kuj, lub melting point ntawm cov muab tub lim hlau yog tsawg, thiab cov txheej txheem yog zoo, tab sis tus nqi ntawm cov muab tub lim hlau yog siab, thiab nws yog feem ntau siv rau welding. qhov chaw nrog cov kev xav tau siab dua.Brazing feem ntau yog siv rau steel thiab tooj liab alloy workpieces nrog loj zog, thiab rau cov cuab yeej brazing.Brazed sib koom lub zog ntawm 200 ~ 490MPa,

Lus Cim: Qhov chaw sib cuag ntawm cov khoom siv hauv paus yuav tsum huv heev, yog li cov flux yuav tsum tau siv.Lub luag hauj lwm ntawm cov flux yog tshem tawm cov oxide thiab roj impurities nyob rau saum npoo ntawm lub hauv paus hlau thiab muab tub lim hlau, tiv thaiv qhov sib cuag ntawm lub muab tub lim hlau thiab lub hauv paus hlau los ntawm oxidation, thiab ua rau kom lub wettability thiab capillary fluidity ntawm lub muab tub lim. hlau.Lub melting point ntawm cov flux yuav tsum qis dua cov hlau muab tub lim, thiab corrosion ntawm flux residue rau lub hauv paus hlau thiab cov pob qij txha yuav tsum tsawg dua.Qhov sib xyaw brazing flux yog rosin los yog zinc chloride tov, thiab cov sib xyaw brazing flux yog sib xyaw ntawm borax, boric acid thiab alkaline fluoride.

Raws li qhov sib txawv ntawm cov cua sov los yog cua sov txoj kev brazing tuaj yeem muab faib ua:nplaim brazing, induction brazing, rauv brazing, dip brazing, kuj brazing thiab lwm yam.Vim tias qhov kub ntawm qhov cua sov yog qhov qis thaum lub sij hawm brazing, nws tsis tshua muaj kev cuam tshuam rau kev ua haujlwm ntawm cov khoom siv ua haujlwm, thiab qhov kev ntxhov siab deformation ntawm vuam kuj tseem me me.Txawm li cas los xij, lub zog ntawm brazed sib koom feem ntau yog qis, thiab cov cua sov tsis zoo.

Brazing cua sov txoj kev:Yuav luag txhua qhov chaw cua sov tuaj yeem siv los ua cov khoom siv hluav taws xob, thiab raws li qhov kev sib tsoo no tau muab cais tawm.

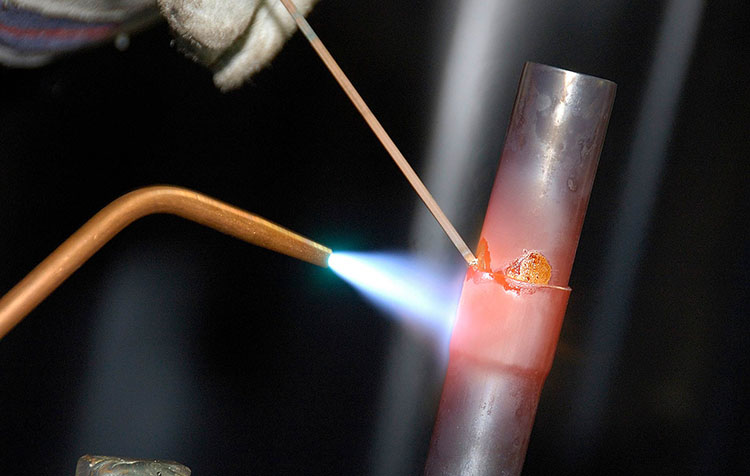

Nplaim brazing:cua sov nrog cov nplaim taws, siv rau carbon steel, stainless hlau, carbide, cam khwb cia hlau, tooj liab thiab tooj liab alloys, aluminium thiab aluminium alloy brazing.

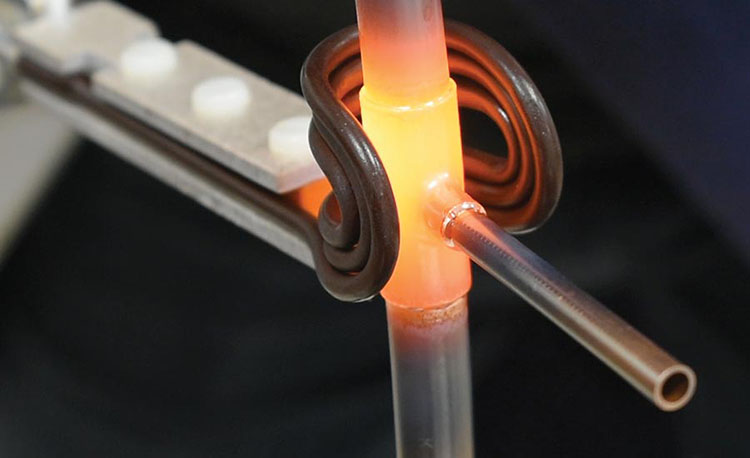

Induction brazing:Kev siv alternating magnetic teb los tsim ib tug induced tam sim no nyob rau hauv ib feem ntawm cov kuj kub cua sov welding, rau ib tug symmetrical zoo ntawm lub vuam, tshwj xeeb tshaj yog lub brazing ntawm cov yeeb nkab ncej.

Dip brazing:qhov vuam yog ib feem los yog tag nrho raus rau hauv molten ntsev sib tov los yog solder yaj, cia siab rau lub tshav kub ntawm cov kua xov xwm mus cuag cov txheej txheem brazing, uas yog yus muaj los ntawm ceev cua sov, uniform kub, me me deformation ntawm vuam ib feem.

Rauv brazing:Cov welds yog cua sov los ntawm lub qhov cub ua haujlwm, uas tuaj yeem tiv thaiv cov welds los ntawm lub tshuab nqus tsev lossis siv cov pa roj tsawg lossis inert gases.

Tsis tas li ntawd, muaj cov hlau brazing, tsis kam brazing, diffusion brazing, infrared brazing, tshuaj tiv thaiv brazing, electron beam brazing, laser brazing, thiab lwm yam.

Brazing tuaj yeem siv rau vuam carbon steel, stainless hlau, superalloy, txhuas, tooj liab thiab lwm yam ntaub ntawv hlau, thiab tseem tuaj yeem txuas cov hlau sib txawv, hlau thiab tsis yog hlau.Haum rau vuam pob qij txha nrog me me load los yog ua hauj lwm nyob rau hauv chav tsev kub, tshwj xeeb tshaj yog haum rau precision, micro thiab complex multi-brazed welds.

Post lub sij hawm: Jul-06-2023