-FLUX-

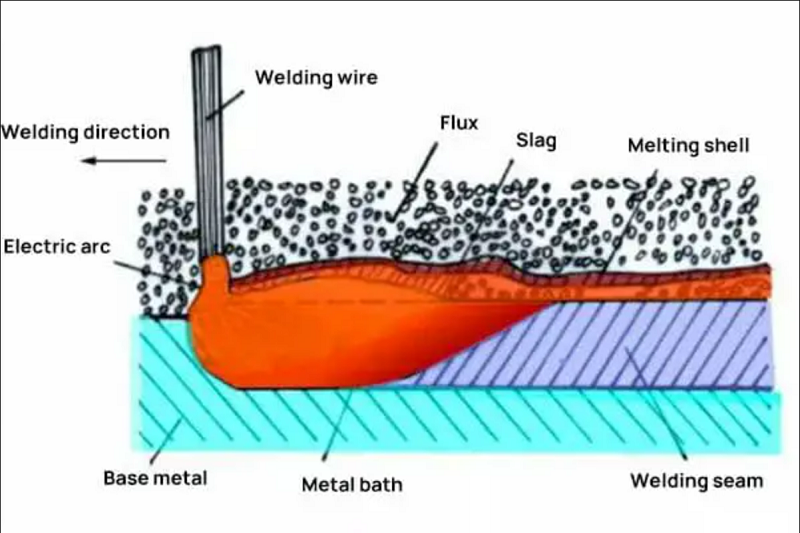

Fluxyog granular welding khoom.Thaum lub sij hawm vuam, nws tuaj yeem yaj los ua slag thiab roj, uas ua lub luag haujlwm tiv thaiv thiab metallurgical ntawm lub pas dej molten.

Cov ntsiab lus

Flux yog tsim los ntawm marble, quartz, fluorite thiab lwm yam ores thiab titanium dioxide, cellulose thiab lwm yam tshuaj.Flux yog tsuas yog siv rau submerged arc vuam thiab electroslag vuam.Thaum siv rau vuam txhua yam hlau thiab cov hlau tsis muaj hlau, nws yuav tsum tau siv tsim nyog nrog cov khoom siv vuam hlau kom tau txais kev txaus siab.

Kev faib tawm

Muaj ntau txoj kev faib tawm ntawm flux, raws li kev siv, kev tsim khoom, tshuaj muaj pes tsawg leeg, vuam thiab metallurgical zog ntawm kev faib tawm, tab sis kuj raws li pH ntawm flux, flux granularity faib.Txawm hais tias hom kev faib tawm hom twg, tsuas yog cuam tshuam cov yam ntxwv ntawm flux los ntawm qee yam, nws tsis tuaj yeem suav tag nrho cov yam ntxwv ntawm flux.Cov txheej txheem kev faib ua feem siv yog:

1. Tsis muaj flux

Neutral flux yog hais txog cov flux uas tsis hloov pauv cov tshuaj muaj pes tsawg leeg ntawm cov hlau fused thiab cov tshuaj muaj pes tsawg leeg ntawm cov vuam hlau tom qab vuam.Neutral flux yog siv rau ntau qhov kev vuam, tshwj xeeb tshaj yog rau vuam ntawm lub hauv paus hlau nrog lub thickness ntau dua 25mm.Neutral flux muaj cov yam ntxwv hauv qab no:

ib.Lub flux yeej tsis muaj SiO2, MnO, FeO thiab lwm yam oxides.

b.Flux tsis muaj kev cuam tshuam oxidation ntawm cov hlau vuam hauv paus.

c.Thaum vuam puag hlau nrog hnyav oxidation, qhov pores thiab weld tawg yuav raug tsim.

2. Active flux

Active flux hais txog qhov sib ntxiv ntawm me me ntawm Mn, Si deoxidizer flux.Nws tuaj yeem txhim kho qhov tsis kam rau porosity thiab tawg.Active flux muaj cov yam ntxwv hauv qab no:

ib.Vim lub deoxidizer, Mn thiab Si hauv cov hlau molten yuav hloov nrog lub arc voltage.Qhov nce ntawm Mn thiab Si yuav ua rau kom lub zog ntawm cov hlau molten thiab txo qhov cuam tshuam toughness.Yog li ntawd, arc voltage yuav tsum nruj me ntsis tswj thaum multi-pass vuam.

b.Active flux muaj zog porosity kuj.

3. Alloy flux

Alloy flux ntxiv cov khoom siv hlau ntxiv rau kev hloov pauv ntawm cov ntsiab lus alloying, feem ntau ntawm cov alloying flux yog sintered flux.Alloy flux yog tsuas yog siv rau vuam ntawm cov hlau tsis tshua muaj hlau thiab hnav-resistant surfacing.

4. Melt flux

Melt flux yog raw cov ntaub ntawv ntawm ntau yam minerals tov nyob rau hauv raws li qhov muab piv, rhuab mus rau ntau tshaj 1300 degrees, melted thiab stirred tusyees, thiab ces txias nyob rau hauv dej rau granulate.Tom qab ziab, sib tsoo, tshuaj ntsuam, ntim siv.

Lub hom phiaj ntawm domestic melting flux yog qhia los ntawm "HJ".Thawj tus lej tom qab nws qhia cov ntsiab lus ntawm MnO, tus lej thib ob qhia txog cov ntsiab lus ntawm SiO2 thiab CaF2, thiab tus lej thib peb qhia cov npe sib txawv ntawm tib hom flux.

5. Sintering flux

Nws yog qhuav tov raws li muab faib ua feem ntawm cov khoom xyaw, thiab ces ntxiv binder (dej iav) rau ntub sib tov, thiab ces granulation, thiab ces xa mus rau lub tshuab ziab khaub ncaws curing, ziab, thiab thaum kawg sintered los ntawm txog 500 degrees.

Lub hom phiaj ntawm domestic sintered flux yog sawv cev los ntawm "SJ", thawj tus lej tom qab ntawd sawv cev rau lub tshuab slag, thiab tus lej thib ob thiab tus lej thib peb sawv cev rau cov npe sib txawv ntawm tib lub tshuab slag flux.

Post lub sij hawm: May-04-2023