Cov txheej txheej ua rau cov tshuaj tiv thaiv metallurgical complex thiab lub cev thiab tshuaj hloov pauv hauv cov txheej txheem vuam, uas yooj yim kov yeej cov teeb meem hauv vuam ntawm cov duab electrode, yog li cov txheej kuj yog ib qho tseem ceeb los txiav txim siab qhov zoo ntawm cov hlau vuam.

Electrode txheej:Hais txog txheej txheej ntawm cov khoom zoo granular nrog cov khoom sib txawv ntawm lub cev thiab tshuaj lom neeg sib xyaw ua ke rau ntawm qhov chaw ntawm vuam core.

Lub luag haujlwm ntawmvuam electrodetxheej:Nyob rau hauv cov txheej txheem vuam, nws tsim slag nrog qhov tsim nyog melting point, viscosity, ntom, alkalinity thiab lwm yam khoom ntawm lub cev thiab tshuaj, kom ruaj khov arc combustion, ua rau cov tee hlau hloov tau yooj yim, tsim ib qho chaw nyob ib ncig ntawm arc cheeb tsam thiab molten pas dej ua ke los tiv thaiv. qhov chaw vuam, thiab tau txais kev sib txuas zoo thiab kev ua haujlwm zoo.Los ntawm kev ntxiv deoxidizer, alloying caij lossis qee cov ntsiab lus ntawm cov hmoov hlau rau txheej, nws tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm vuam hlau kev ua tau zoo los yog txhim kho cov melting efficiency.

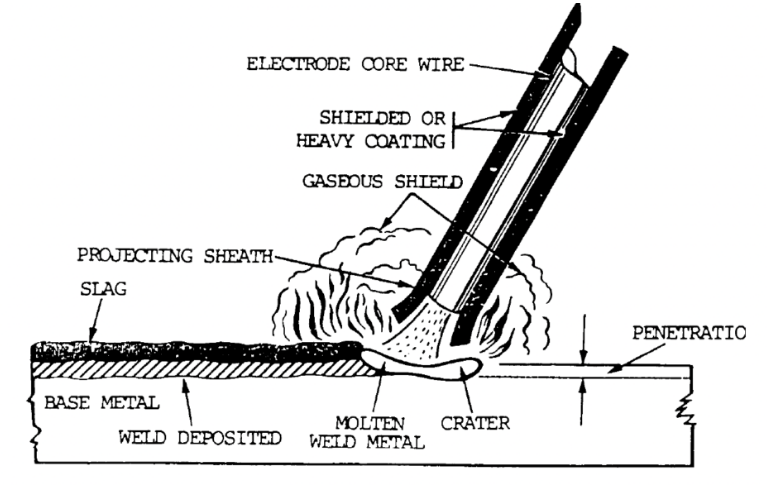

Lub hauv paus ntsiab lus ntawm electrode arc vuam:

1. Tshuaj tawv nqaij

2. Weld core

3. Tiv thaiv roj

4: Arc

5. Lub pas dej ua ke

6. Cov khoom siv hauv paus

7. Weld

8. Vuam slag

9. Slag

10. Qhuav dej

Ntau yam khoom siv raw raws li lawv lub luag haujlwm hauv electrode txheej tuaj yeem muab faib ua:

(1) Arc stabilizer

Lub luag haujlwm tseem ceeb yog ua kom cov electrode yooj yim pib arc thiab ua kom lub arc ruaj khov combustion hauv cov txheej txheem vuam.Raws li arc stabilizer raw cov ntaub ntawv yog feem ntau muaj qee tus naj npawb ntawm cov ionization tsis tshua muaj peev xwm yooj yim ionizing ntsiab lus, xws li feldspar, sodium silicate, rutile, titanium dioxide, marble, mica, ilmenite, txo ilmenite thiab lwm yam.

(2) Gas ua tus neeg sawv cev

Nyob rau hauv qhov kev txiav txim siab kub arc decomposition gas, tsim ib qho chaw tiv thaiv, tiv thaiv arc thiab molten hlau, tiv thaiv kev nkag ntawm oxygen thiab nitrogen nyob rau hauv ib puag ncig huab cua.Feem ntau siv roj ua cov neeg ua haujlwm yog carbonate (xws li marble, dolomite, rhombic acid, barium carbonate, thiab lwm yam) thiab cov organic teeb meem (xws li ntoo hmoov, hmoov txhuv nplej siab, cellulose, resin, thiab lwm yam).

(3) Deoxidizer (tseem hu ua txo tus neeg sawv cev)

Cov ntsiab lus ntawm cov pa oxygen hauv weld hlau tuaj yeem raug txo qis thiab kev ua haujlwm ntawm cov hlau vuam tuaj yeem txhim kho los ntawm cov tshuaj metallurgical cov tshuaj tiv thaiv hauv cov txheej txheem vuam.Deoxidizer feem ntau muaj cov hlau alloy thiab hlau hmoov nrog zoo affinity rau oxygen.Feem ntau siv deoxidizer yog ferromanganese, ferrosilicon, ferrotitanium, ferroaluminum, silicon calcium alloy, thiab lwm yam.

(4) Plasticizer

Nws lub luag haujlwm tseem ceeb yog txhawm rau txhim kho cov yas, elasticity thiab fluidity nyob rau hauv cov txheej txheem ntawm electrode raug nias txheej, txhim kho cov txheej txheem zoo ntawm cov electrode, kom lub ntsej muag du ntawm cov electrode txheej tsis tawg.Feem ntau xaiv ib qho elasticity, nplua los yog nqus tau tom qab qee yam kev nthuav dav ntawm cov ntaub ntawv, xws li mica, av nkos dawb, titanium dioxide, talc, iav dej khov, cellulose, thiab lwm yam.

(5) Alloy tus neeg sawv cev

Nws yog siv los them nyiaj rau kev kub nyhiab ntawm cov hlau alloying hauv cov txheej txheem vuam thiab hloov cov ntsiab lus alloying rau vuam, thiaj li ua kom cov tshuaj muaj pes tsawg leeg thiab cov khoom ntawm cov hlau vuam.Raws li qhov yuav tsum tau xaiv ntau yam ferroalloys (xws li ferromanganese, ferrosilicon, ferrochrome, hlau thiab hlau, ferric vanadium, ferric niobium, ferric boron, tsis tshua muaj ntiaj teb ferrosilicon, thiab lwm yam) los yog cov hlau ntshiab (xws li manganese hlau, chromium hlau. , nickel hmoov, tungsten hmoov, thiab lwm yam).

(6) Slag ua tus neeg sawv cev

Vuam tuaj yeem tsim cov khoom siv lub cev thiab tshuaj lom neeg ntawm molten slag, tiv thaiv cov welding droplet thiab molten pas dej ua ke, txhim kho kev tsim vuam, raws li tus neeg sawv cev ntawm cov khoom siv raw yog marble, fluorite, dolomite, magnesia, feldspar, av nkos dawb, mica, quartz. , rutile, titanium dioxide, ilmenite, thiab lwm yam.

(7) Cov ntaub ntawv

Cov khoom siv txheej yog ruaj khov rau cov tub ntxhais vuam, thiab cov txheej txheem electrode muaj qee lub zog tom qab ziab.Nyob rau hauv tus txheej txheem ntawm welding metallurgy, tsis muaj teeb meem cuam tshuam rau lub pas dej ua ke thiab vuam hlau.Feem ntau siv binders yog sodium silicate (poov tshuaj, sodium thiab tov sodium silicate) thiab phenolic resin, pos hniav, thiab lwm yam.

Post lub sij hawm: May-04-2023