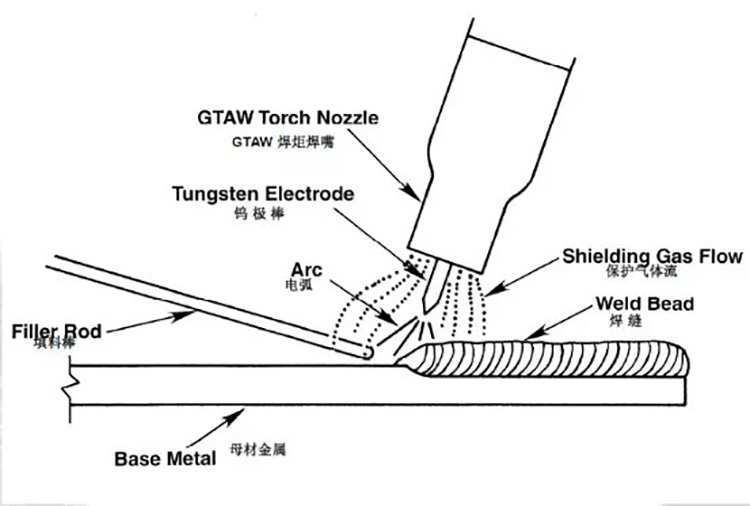

Argon tungsten arc vuam siv argon ua cov roj thaiv kom sov thiab yaj cov khoom siv vuam nws tus kheej (nws kuj yog yaj thaum cov hlau muab tub lim ntxiv) los ntawm kev siv cov arc generated ntawm tungsten electrode thiab vuam lub cev, thiab tom qab ntawd ua cov vuam. ntawm txoj kev weld hlau.Covtungsten electrode,weld pas dej ua ke, arc thiab sib koom seam cheeb tsam rhuab los ntawm arc yog tiv thaiv los ntawm atmospheric paug los ntawm argon ntws.

Thaum lub sij hawm argon arc vuam, tus txheeb ze txoj hauj lwm ntawm lub teeb, muab tub lim hlau thiab vuam yog raws li qhia nyob rau hauv daim duab hauv qab no: lub arc ntev yog feem ntau 1 ~ 1.5 npaug ntawm txoj kab uas hla ntawm tungsten electrode.Thaum lub vuam nres, cov hlau muab tub lim yog thawj zaug muab rho tawm los ntawm lub pas dej molten (cov hlau muab tub lim ntxiv raws li qhov tuab ntawm cov vuam), thiab qhov kub kawg tseem yuav tsum nyob hauv kev tiv thaiv ntawm argon ntws los tiv thaiv nws cov oxidation. .

1. Welding torch (teeb)

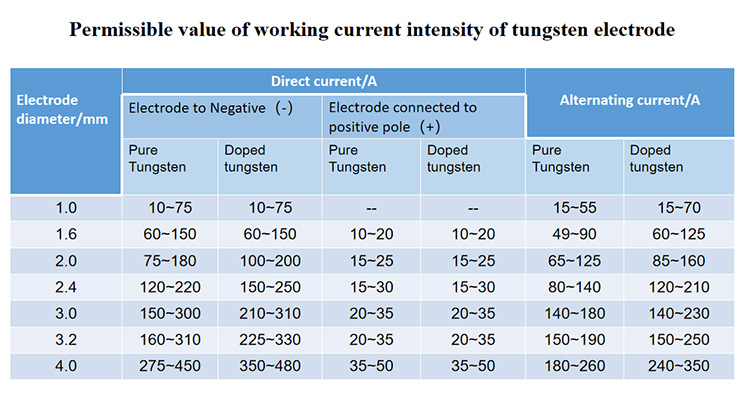

Ntxiv nrog rau clamping lub tungsten electrode thiab xa cov vuam tam sim no, argon tungsten arc vuam teeb (tseem hu ua vuam teeb) kuj tseem yuav tsum tau txau cov roj tiv thaiv.Cov phom welding siab tam sim no yuav tsum tau siv cov phom vuam dej txias rau kev vuam mus ntev.Yog li ntawd, kev siv kom raug thiab kev tiv thaiv ntawm vuam teeb yog qhov tseem ceeb heev.Tungsten electrode load tam sim no muaj peev xwm (A) muaj nyob rau hauv cov lus hauv qab no.

2. Gas txoj kev

Cov roj txoj kev yog tsim los ntawm argon lub tog raj kheej siab txo valve, flow meter, hose thiab electromagnetic gas valve (hauv lub tshuab vuam).Lub siab txo valve yog siv los txo qhov siab thiab kho lub siab ntawm kev tiv thaiv roj.Lub flowmeter yog siv los calibrate thiab kho lub shielding gas flow.Argon arc vuam tshuab feem ntau siv ib qho kev sib xyaw ua ke decompression flowmeter, uas yooj yim thiab txhim khu kev siv.

Thaum lub sij hawm argon arc vuam, qhov yuav tsum tau rau lub purity ntawm argon roj yog hais tias cov chromium-nickel stainless hlau yuav tsum ≥99.7%, thiab cov refractory hlau yuav tsum yog ≥99.98%.

(1) Argon yog ib qho roj inert, thiab nws tsis yooj yim rau hnov mob nrog lwm cov ntaub ntawv hlau thiab roj.Tsis tas li ntawd, vim qhov txias txias ntawm cov huab cua ntws, qhov chaw tshav kub cuam tshuam ntawm cov vuam yog me me thiab deformation ntawm weldment me me.Nws yog qhov zoo tshaj plaws tiv thaiv roj rau argon tungsten arc vuam.

(2) Argon feem ntau yog siv los tiv thaiv lub pas dej molten, tiv thaiv cov huab cua los ntawm eroding lub pas dej molten thiab ua rau oxidation thaum lub sij hawm vuam, thiab tib lub sij hawm zoo cais cov huab cua nyob rau hauv lub weld cheeb tsam, yog li ntawd lub weld cheeb tsam. tiv thaiv thiab vuam kev ua tau zoo dua.

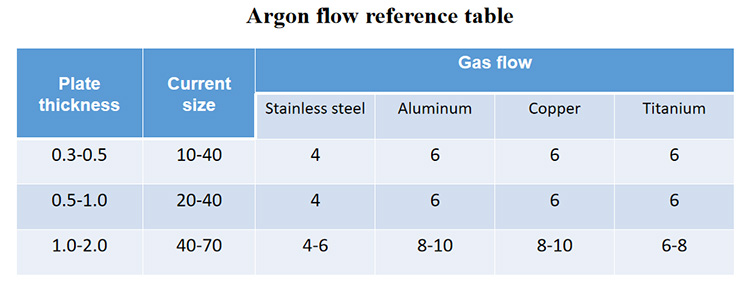

(3) Txoj kev hloov kho yog txiav txim siab raws li cov khoom siv hlau yuav tsum tau welded, qhov loj ntawm qhov tam sim no, thiab cov txheej txheem vuam: qhov ntau dua qhov tam sim no, qhov ntau dua cov roj shielding.Rau cov khoom siv nquag, cov roj tiv thaiv yuav tsum tau ntxiv dag zog kom nce tus nqi ntws.

3. Specification parameters

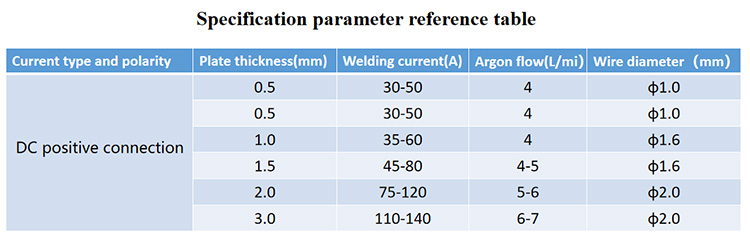

Cov txheej txheem tsis sib xws ntawm argon tungsten arc vuam feem ntau suav nrog tam sim no, voltage, vuam ceev, thiab argon roj ntws, thiab lawv cov txiaj ntsig muaj feem xyuam rau cov khoom siv yuav tsum tau welded, phaj thickness thiab sib koom ua ke.

Qhov seem tsis xws li qhov ntev ntawm tungsten electrode protruding los ntawm lub nozzle feem ntau yog 1-2 npaug ntawm txoj kab uas hla ntawm tungsten electrode, qhov kev ncua deb ntawm tungsten electrode thiab vuam (arc ntev) feem ntau yog 1.5 npaug ntawm txoj kab uas hla ntawm tungsten. electrode, thiab qhov luaj li cas ntawm lub nozzle yog txiav txim siab tom qab vuam tam sim no tus nqi.Xaiv dua.

General stainless hlau argon arc vuam specifications yog raws li nram no:

4. Ntxuav ua ntej vuam

Tungsten argon arc vuam yog rhiab heev rau cov pa phem ntawm lub vuam thiab muab tub lim hlau nto, yog li cov roj, txheej, roj nplua nyeem thiab oxide zaj duab xis ntawm qhov chaw vuam yuav tsum raug tshem tawm ua ntej vuam.

5. Kev nyab xeeb technology

Cov neeg ua haujlwm ntawm argon tungsten arc vuam yuav tsum hnav lub ntsej muag lub taub hau, hnab looj tes, khaub ncaws ua haujlwm, thiab khau ua haujlwm kom tsis txhob muaj kev kub nyhiab ntawm ultraviolet thiab infrared nyob rau hauv arc.Steyr tungsten argon arc vuam cov cav tov yog nruab nrog high-frequency arc starters.Txawm hais tias qhov hluav taws xob tsawg-tsawg high-voltage hluav taws xob yuav tsis cuam tshuam rau tus neeg teb xov tooj, thaum lub rwb thaiv tsev ua haujlwm tsis zoo, cov hluav taws xob ntau zaus yuav hlawv cov tawv nqaij ntawm tus neeg teb xov tooj tes, thiab nws nyuaj rau kev kho, yog li cov rwb thaiv tsev kev ua tau zoo. ntawm vuam kov yuav tsum tau kuaj xyuas ntau zaus.Thaum lub sij hawm argon tungsten arc vuam, qhov cua hauv qhov chaw vuam yuav tsum tau txhim kho.

Nco tseg: Qhov tseem ceeb tshaj plaws yog kev txawj ntse thiab dexterous.Lub thickness ntawm lub rooj tsavxwm, lub sij hawm ntawm kev txhaj tshuaj, thiab qhov tam sim no yog txhua yam cuam tshuam, thiab lawv yuav tsum tau koom tes nrog ib leeg.

Thaum vuam, tsis txhob taw tes rau ntawm qhov chaw vuam thaum pib, thiab ntaus nws khoob ua ntej kom tso pa tawm hauv cov yeeb nkab, kom lub vuam yuav tsis tshuab thiab yuav tsis muaj qhov dub.Ob peb vib nas this, nyob rau hauv txoj kev no, cov hlau tsis muaj zog tiv thaiv los ntawm argon roj thaum lub sij hawm txias, yog li nws yuav tsis dub, thiab txawm tias cov dej ntxuav thiab polishing ntawv tau txais kev cawmdim.Qhov no tsuas yog siv tau rau qhov chaw vuam.Yog tias koj rub vuam mus ntev, tsis muaj txoj hauv kev.Lub rooj tsavxwm yeej yuav hloov xim.Koj yuav tsum tau tos kom polishing thiab tu.

Post lub sij hawm: May-16-2023