Cov neeg siv khoom zoo npe rau Tuam Tshoj Ercocr-B Cobalt-Based Vuam Electrode Hoobkas Nqe

Peb feem ntau ua ib tug neeg ua hauj lwm tangible ua kom paub tseeb tias peb yuav muab koj cov txiaj ntsig zoo tshaj plaws ntxiv rau tus nqi muag zoo tshaj plaws rau Cov Neeg Siv Khoom Zoo rau Tuam Tshoj Ercocr-B Cobalt-BasedVuamElectrode Factory Nqe, Kev lag luam pib, peb nkag siab ib leeg.Kev lag luam ntxiv, kev ntseeg siab tau txais muaj.Peb lub tuam txhab feem ntau ntawm koj qhov kev pabcuam txhua lub sijhawm.

Peb feem ntau ua tau ib tug neeg ua hauj lwm tangible ua kom paub tseeb tias peb yuav muab koj cov txiaj ntsig zoo tshaj plaws ntxiv rau tus nqi muag zoo tshaj plaws rauTuam Tshoj Electrode, Vuam, Tam sim no peb cov khoom muag muag thoob plaws hauv lub tebchaws thiab txawv teb chaws ua tsaug rau cov neeg siv khoom tsis tu ncua thiab kev txhawb nqa tshiab.Peb nthuav tawm cov khoom zoo thiab cov nqi sib tw, txais tos cov neeg siv khoom tsis tu ncua thiab tshiab koom tes nrog peb!

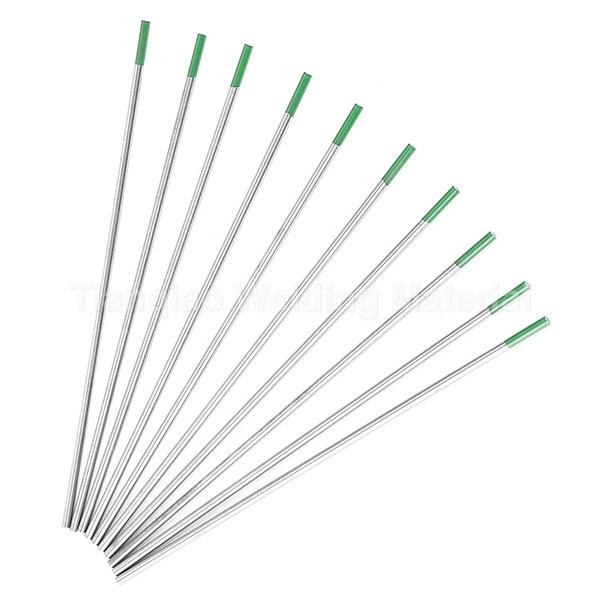

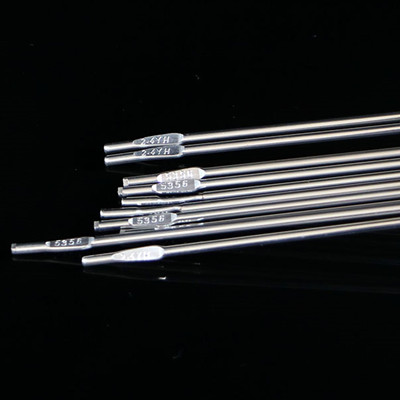

Ntshiab tungsten electrode yog thawj electrode siv hauv TIG vuam.Nws muaj cov yam ntxwv ntawm qhov tsis muaj zog, zoo conductivity thiab thermal expansion, thiab yog dav siv nyob rau hauv ntau yam tshwj xeeb vuam industries.Cov ntshiab tungsten electrode muaj 99.5% qis tungsten thiab tsis muaj alloying ntsiab.Cov ntshiab tungsten electrode tsuas yog siv los ua vuam electrode nyob rau hauv AC tej yam kev mob los yog raws li ib tug kuj welding electrode.Nws tuaj yeem muab cov khoom siv huv huv, thiab lub pob solder ua ntse thaum rhuab.Cov duab no muab qhov sib npaug waveform AC vuam arc stability, uas yog qhov tshwj xeeb zoo.Ntshiab tungsten muaj cov hluav taws xob khiav tawm siab heev, tsis muaj vapor siab, tsis muaj hluav taws xob tsis zoo, hluav taws xob zoo, tsis tshua muaj thermal expansion, thiab elasticity siab.Yog li ntawd, lub arc yog ruaj khov ntawm qhov tsis tshua muaj tam sim no, thiab txhuas, magnesium thiab lawv cov alloys tuaj yeem welded zoo hauv qab 5A.Txawm li cas los xij, qhov emission ntawm electrons yuav tsum muaj qhov hluav taws xob ntau dua, thiab lub tshuab vuam yuav tsum muaj qhov tsis muaj hluav taws xob siab.Lub tungsten electrode hlawv tawm thaum ua haujlwm nrog cov dej ntws loj rau lub sijhawm ntev.Pom tseeb, qhov kawg yuav yaj thiab poob rau hauv lub pas dej molten yuav ua rau cov seam rau clamp tungsten, yog li nws tsuas yog siv rau vuam qee cov hlau, lossis vuam tsis tseem ceeb.

Peb cov tungsten electrode txais cov khoom siv hauv tsev siab heev centerless grinder, thiab qhov chaw ntawm cov khoom muaj qib siab ntawm smoothness thiab tsis muaj burrs.Piv nrog rau lwm yam khoom, lub arc yog ntau concentrated thiab ruaj khov.

Nta:

1. Cov ntshiab tungsten electrode muaj tsawg kawg yog 99.5% tungsten, uas muaj cov conductivity zoo thiab kav ntev.

2. Tsis yog-radioactive tungsten electrode, tsis muaj kuab paug.

3. Tsawg burnout tus nqi thiab zoo arc stability.

4. Muab 9 qhov tshwj xeeb ntawm cov ntshiab tungsten electrodes kom tau raws li koj qhov kev xav tau sib txawv.

5. Feem ntau yog siv rau AC vuam ntawm nickel alloy, magnesium aluminium thiab nws cov alloys.

Qauv: WP

Khoom siv:Tungsten

Kev faib tawm: ANSI/AWS A5.12M-98TS EN ISO 6848 Cov

Ntim:10pcs / thawv

Vuam tam sim no: thov mus saib cov lus hauv qab no

Xim xim: ntsuab

Xaiv qhov loj me:

| 1.0 * 150mm / 0.04 * 5.91 nti | 1.0 * 175mm / 0.04 * 6.89 nti |

| 1.6 * 150mm / 0.06 * 5.91 nti | 1.6 * 175mm / 0.06 * 6.89 nti |

| 2.0 * 150mm / 0.08 * 5.91 nti | 2.0 * 175mm / 0.08 * 6.89 nti |

| 2.4 * 150mm / 0.09 * 5.91 nti | 2.4 * 175mm / 0.09 * 6.89 nti |

| 3.2 * 150mm / 0.13 * 5.91 nti | 3.2 * 175mm / 0.13 * 6.89 nti |

Qhov hnyav: txog 50-280 grams / 1.8-9.9 ooj

Sib piv TABLE NTAWM TUNGSTEN ELECTRODE DIAmeter thiab tam sim no

| DIAMETER | DC- (A) | DC + (A) | AC |

| 1.0 hli | 10-75 A | 1-10 A | 15-70 A |

| 1.6mm ib | 60-150 A | 10-20 A | 60-125 A |

| 2.0 hli | 100-200 A | 15-25 A | 85-160 A |

| 2.4mm ib | 170-250 A | 17-30 IB | 120-210 IB |

| 3.0mm ib | 200-300 A | 20-25 A | 140-230 Ib |

| 3.2mm ib | 225-330 Ib | 30-35 A | 150-250 A |

| 4.0mm ib | 350-480 A | 35-50 A | 240-350 A |

| 5.0mm ib | 500-675 A | 50-70 A | 330-460 Ib |

| Thov xaiv qhov sib thooj tungsten electrode specifications raws li koj siv tam sim no | |||

Daim ntawv thov:

Ntshiab tungsten electrode tsis ntxiv tej yam tsawg lub ntiaj teb oxides thiab muaj qhov tsawg tshaj plaws electron emission muaj peev xwm, yog li nws tsuas yog haum rau vuam nyob rau hauv AC hnyav load tej yam kev mob, xws li vuam ntawm txhuas thiab txhuas-magnesium alloys.

Cov Cim Tseem Ceeb:

| Qauv | Ntxiv impurity | impurity tus nqi% | Lwm yam Cov impurities% | Tungsten% | Hluav taws xob tso tawm zog | Xim kos npe |

| WP | - | - | <0.20 | Tus so | 4.5 | Ntsuab |

Peb feem ntau ua ib tug neeg ua hauj lwm tangible ua kom paub tseeb tias peb yuav muab koj cov txiaj ntsig zoo tshaj plaws ntxiv rau tus nqi muag zoo tshaj plaws rau Cov Neeg Siv Khoom Zoo rau Tuam Tshoj Ercocr-B Cobalt-Based Welding Electrode Hoobkas Nqe, Pib lag luam, peb to taub ib leeg.Kev lag luam ntxiv, kev ntseeg siab tau txais muaj.Peb lub tuam txhab feem ntau ntawm koj qhov kev pabcuam txhua lub sijhawm.

Cov neeg siv Reputation zoo rauTuam Tshoj Electrode, Vuam, Tam sim no peb cov khoom muag muag thoob plaws hauv lub tebchaws thiab txawv teb chaws ua tsaug rau cov neeg siv khoom tsis tu ncua thiab kev txhawb nqa tshiab.Peb nthuav tawm cov khoom zoo thiab cov nqi sib tw, txais tos cov neeg siv khoom tsis tu ncua thiab tshiab koom tes nrog peb!