Electrode arc vuam yog qhov dav siv vuam txoj kev hauv kev tsim khoom.Cov hlau yuav tsum tau welded yog ib tug ncej, thiab lub electrode yog lwm tus ncej.Thaum ob tug ncej nyob ze rau ib leeg, ib qho arc yog generated.Thaum tshav kub kub generated los ntawm arc tawm (feem ntau hu ua arc combustion) yog siv los txuas cov electrode nrog cov workpieces yaj ib leeg thiab tsim ib tug weld tom qab condensing, thiaj li yuav tau ib tug welding txheej txheem nrog ib tug muaj zog sib koom tes.

Daim duab 1. Keeb kwm ntawm vuam

Keeb kwm luv luv

Tom qab ntau qhov kev sim vuam thaum ntxov li xyoo 19th, ib tug neeg Askiv hu ua Willard thawj zaug tau txais daim ntawv pov thawj rau arc vuam nyob rau hauv 1865. Nws siv hluav taws xob tam sim no los ntawm ob daim hlau me me kom ua tiav lawv, thiab nyob rau hauv li nees nkaum xyoo tom qab, ib tug neeg Lavxias. npe Bernard tau txais patent rau txoj kev vuam arc.Nws tuav lub arc nruab nrab ntawm cov pa roj carbon ncej thiab cov workpieces.Thaum lub arc yog manually ua los ntawm kev sib koom ua ke ntawm lub workpieces, lub workpieces yuav tsum tau welded yog fused ua ke.Nyob rau xyoo 1890, cov hlau tau tsim los ua cov khoom siv hluav taws xob, uas tau siv rau hauv lub pas dej molten thiab tau los ua ib feem ntawm cov hlau vuam.Txawm li cas los xij, cov pa oxygen thiab nitrogen hauv huab cua tsim teeb meem oxides thiab nitrides hauv cov hlau welding., Yog li ua rau cov vuam tsis zoo.

Nyob rau hauv lub xyoo pua 20th, qhov tseem ceeb ntawm kev tiv thaiv lub arc kom tsis txhob muaj huab cua infiltration, thiab kev siv cov arc tshav kub kom decompose cov txheej rau hauv electrode ntawm cov ntaub thaiv npog roj los ua txoj kev zoo tshaj plaws.Nyob rau hauv nruab nrab-1920s, lub coated electrode tau tsim, uas zoo heev txhim kho qhov zoo ntawm welded hlau.Nyob rau tib lub sijhawm, nws kuj tseem yog qhov tseem ceeb tshaj plaws ntawm kev hloov pauv ntawm arc vuam.Cov cuab yeej siv tseem ceeb hauv cov txheej txheem vuam muaj xws li hluav taws xob vuam tshuab, vuam vuam thiab daim npog ntsej muag.

Daim duab 2. Lub hauv paus ntsiab lus ntawm vuam

Daim duab 2. Lub hauv paus ntsiab lus ntawm vuam

Txoj Cai

Lub vuam arc yog siv los ntawm qhov chaw vuam fais fab.Nyob rau hauv qhov kev txiav txim ntawm ib qho hluav taws xob, qhov tshwm sim muaj zog thiab kav ntev tshwm sim ntawm cov electrode (thiab qhov kawg ntawm vuam hlau los yog vuam pas nrig) thiab cov khoom ua haujlwm.Lub ntsiab lus ntawm vuam arc yog cov roj conduction, uas yog, cov pa nruab nrab hauv qhov chaw uas lub arc nyob yog decomposed rau hauv qhov zoo nqi ions thiab tsis zoo electrons nyob rau hauv qhov kev txiav txim ntawm ib tug tej yam voltage, uas yog hu ua ionization.Ob qho khoom siv hluav taws xob no raug coj mus rau ob tus ncej.Kev taw qhia txav ua rau cov pa hauv zos ua hluav taws xob los ua ib qho arc.Cov hluav taws xob arc hloov hluav taws xob hluav taws xob mus rau hauv tshav kub, uas ua kom sov thiab yaj cov hlau los ua ib qho kev sib koom ua ke.

Tom qab lub arc raug ntxias kom "ignite", cov txheej txheem tawm ntawm nws tus kheej tuaj yeem tsim cov khoom siv hluav taws xob uas xav tau los txhawb nqa qhov tawm, uas yog qhov tshwm sim ntawm tus kheej tawm.Thiab cov txheej txheem arc tawm muaj tsawg voltage, siab tam sim no, kub kub thiab muaj zog luminescence.Nrog rau cov txheej txheem no, hluav taws xob hluav taws xob hloov mus rau hauv tshav kub, txhua yam thiab lub teeb lub zog.Vuam mas siv nws cov thermal thiab mechanical zog kom ua tiav lub hom phiaj ntawm kev sib txuas hlau.

Thaum lub sij hawm welding, lub arc kub ntawm lub vuam pas nrig thiab vuam workpieces, melting lub workpieces thiab electrode cores los ua ib tug molten pas dej ua ke.Nyob rau tib lub sijhawm, cov txheej txheej electrode kuj melted, thiab cov tshuaj tiv thaiv tshwm sim los ua slag thiab roj, uas tiv thaiv qhov kawg ntawm electrode, tee dej, molten pas dej ua ke thiab high-temperature weld hlau.

Kev faib loj

Cov txheej txheem arc vuam feem ntau suav nrog Shielded Hlau Arc Vuam (SMAW), Submerged Arc Vuam (SAW), Gas Tungsten Arc Weld (GTAW lossis TIG welding), Plasma Arc Vuam (PAW) thiab Gas Hlau Arc Vuam (GMAW, MIG lossis MAG vuam. ) lwm.

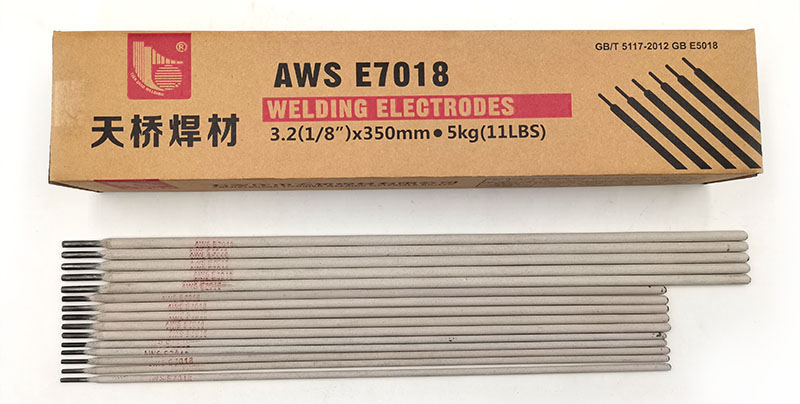

Daim duab 3. E7018 vuam electrode

Shielded Hlau Arc Vuam (SMAW)

Shielded hlau arc vuam siv cov electrode thiab lub workpiece ua ob electrodes, thiab lub tshav kub thiab tshuab quab yuam ntawm lub arc yog siv rau hauv zos yaj lub workpiece thaum vuam.Nyob rau tib lub sij hawm, nyob rau hauv qhov kev txiav txim ntawm arc tshav kub, qhov kawg ntawm lub electrode yog melted los ua ib tug tee dej, thiab lub workpiece yog ib nrab melted los ua ib tug oval pit uas muaj kua hlau.Lub molten kua hlau thiab cov tee dej ntawm lub workpiece tsim ib lub pas dej molten.Thaum lub sij hawm vuam txheej txheem, cov txheej thiab cov hlau tsis yog cov khoom sib xyaw ua ke thiab tsim cov khoom tsis yog xim hlau npog qhov chaw ntawm cov vuam los ntawm kev hloov tshuaj hu ua slag.Thaum lub arc txav mus, lub pas dej molten txias thiab solidifies los tsim ib tug weld.Peb muaj ntau yam vuam electrode rau SMAW, feem ntau nrov qauv yogE6010, E6011, E6013, ua 7016, ua 7018, thiab raustainless hlau, nrum hlau, nyuaj ntolwm.

Daim duab 4. Submerged arc vuam

Daim duab 4. Submerged arc vuam

Submerged Arc Welding (SAW)

Submerged arc vuam yog ib txoj hauv kev uas cov arc hlawv hauv qab txheej txheej rau vuam.Cov hlau electrode siv nyob rau hauv submerged arc vuam yog ib tug liab qab hlau uas yog cia li pub nyob rau hauv tsis muaj kev cuam tshuam.Feem ntau, vuam trolley lossis lwm yam khoom siv hluav taws xob thiab hluav taws xob yog siv los paub txog qhov tsis siv neeg txav ntawm lub arc thaum lub vuam txheej txheem.Lub arc ntawm submerged arc vuam kub kub nyob rau hauv lub granular flux.Lub tshav kub ntawm lub arc melts thiab evaporates cov khoom ncaj qha los ntawm lub arc ntawm lub workpiece, qhov kawg ntawm vuam hlau thiab cov flux, thiab cov vapor ntawm cov hlau thiab flux evaporates los tsim ib tug kaw kab noj hniav nyob ib ncig ntawm lub arc.Hlawv hauv kab noj hniav no.Cov kab noj hniav yog surrounded los ntawm ib tug slag zaj duab xis tsim los ntawm slag tsim los ntawm flux melting.Cov zaj duab xis slag no tsis tsuas zoo cais cov huab cua los ntawm kev sib cuag nrog lub arc thiab lub pas dej molten, tab sis kuj tiv thaiv lub arc ntawm radiating tawm.Lub vuam hlau rhuab thiab melted los ntawm arc ntog nyob rau hauv daim ntawv ntawm tee thiab sib tov nrog molten workpiece hlau los ua ib tug molten pas dej ua ke.Qhov tsawg ntom slag ntab rau ntawm lub pas dej molten.Ntxiv nrog rau kev sib cais thiab kev tiv thaiv ntawm lub pas dej molten hlau, lub molten slag kuj tau txais cov tshuaj tiv thaiv metallurgical nrog lub pas dej molten hlau thaum lub sij hawm vuam, yog li cuam tshuam cov tshuaj muaj pes tsawg leeg ntawm cov hlau weld.Lub arc txav mus rau pem hauv ntej, thiab lub pas dej molten hlau maj mam txias thiab crystallizes los ua ib tug weld.Tom qab lub molten slag ntab rau sab sauv ntawm lub pas dej molten txias, lub slag crust yog tsim los txuas ntxiv los tiv thaiv cov vuam ntawm qhov kub thiab tiv thaiv nws los ntawm oxidized.Peb muab cov flux rau SAW,SJ 101,SJ301,SJ302

Daim duab 5. Gas Tungsten Arc Weld-TIG

Daim duab 5. Gas Tungsten Arc Weld-TIG

Gas Tungsten Arc Weld/Tungsten Inert Gas Vuam (GTAW or TIG)

TIG welding yog hais txog ib qho kev vuam arc uas siv tungsten lossis tungsten alloy (thorium tungsten, cerium tungsten, thiab lwm yam) raws li cov khoom siv hluav taws xob thiab argon ua cov roj tiv thaiv, hu ua TIG vuam lossis GTAW vuam.Thaum lub sij hawm vuam, muab tub lim hlau tuaj yeem muab ntxiv lossis tsis ntxiv raws li daim ntawv zawj ntawm qhov vuam thiab kev ua haujlwm ntawm cov hlau vuam.Filler hlau feem ntau yog ntxiv los ntawm pem hauv ntej ntawm lub arc.Vim qhov tshwj xeeb ntawm aluminium-magnesium thiab nws cov ntaub ntawv alloy, AC tungsten arc vuam yuav tsum tau siv rau vuam, thiab DC tungsten arc vuam yog siv rau lwm cov ntaub ntawv hlau.Txhawm rau tswj cov khoom siv hluav taws xob, cov khoom siv hluav taws xob argon tungsten arc vuam yog siv ntau thiab ntau dua.Feem ntau siv TIG vuam hlau yogAWS ER70S-6, ER80S-G,TIAB SA 4043,TIAB SA 5356,TIAB SA 221thiab lwm yam.

Daim duab 5. Plasma Arc Vuam

Daim duab 5. Plasma Arc Vuam

Plasma Arc Vuam (PAW)

Plasma arc yog ib daim ntawv tshwj xeeb ntawm arc.Lub arc kuj tseem yog tungsten lossis tungsten alloy (thorium tungsten, cerium tungsten, thiab lwm yam) raws li arc electrode, siv argon ua cov roj tiv thaiv, tab sis cov tungsten electrode tsis txuas tawm ntawm lub nozzle, tab sis thim rov qab hauv lub nozzle, lub nozzle. yog dej txias, tseem hu ua dej txias nozzle.Cov roj inert yog muab faib ua ob ntu, ib feem yog cov roj ejected ntawm tungsten electrode thiab cov dej-txias nozzle, hu ua ion gas;Lwm qhov yog cov roj ejected ntawm cov dej-txias nozzle thiab cov roj tiv thaiv hood, hu ua Shielding gas, siv plasma arc los ua cua sov rau vuam, txiav, txau, surfacing, thiab lwm yam.

Daim duab 5 Hlau-Inert Gas Vuam

Daim duab 5 Hlau-Inert Gas Vuam

Hlau Inert Gas Vuam (MIG)

MIG vuam txhais tau hais tias cov vuam hlau hloov cov tungsten electrode.Lub vuam hlau nws tus kheej yog ib tug ntawm cov ncej ntawm lub arc, ua si lub luag hauj lwm ntawm hluav taws xob conduction thiab arcing, thiab nyob rau tib lub sij hawm raws li cov khoom filling, uas yog tsis tu ncua melted thiab sau rau hauv lub weld nyob rau hauv qhov kev txiav txim ntawm lub arc.Cov roj tiv thaiv feem ntau siv nyob ib ncig ntawm lub arc tuaj yeem yog cov roj inert Ar, cov pa roj CO2, or the Ar+CO2sib xyaw gas.MIG welding uas siv Ar li shielding gas hu ua MIG vuam;MIG welding uas siv CO2raws li shielding gas hu ua CO2vuam.Qhov nrov tshaj plaws yog MIGAWS ER70S-6, ER80S-G.

Post lub sij hawm: Aug-17-2021