Shielded Hlau Arc Vuam (abbreviated li SMAW).Lub hauv paus ntsiab lus yog: ib qho arc yog tsim los ntawm cov coated electrode thiab lub hauv paus hlau, thiab txoj kev vuam siv lub arc cua sov kom yaj cov electrode thiab lub hauv paus hlau.Lub txheej txheej ntawm cov electrode yog them nrog vuam flux thiab melts thaum raug tshav kub, uas muaj lub luag hauj lwm ntawm stabilizing lub arc, tsim slag, deoxidizing, thiab refining.Vim nws xav tau cov cuab yeej siv yooj yim thiab kev ua haujlwm yooj yim, nws tuaj yeem yooj yim welded rau welds tsim los ntawm ntau txoj haujlwm thiab cov pob qij txha sib txawv hauv qhov chaw.Yog li ntawd, nws tseem siv dav hauv tam sim no.

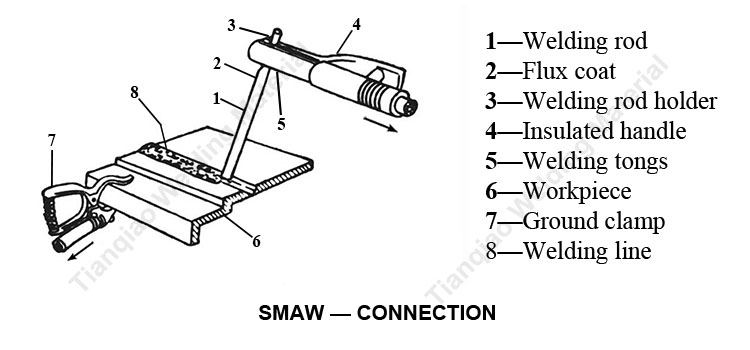

Daim duab 1: Shielded Hlau Arc Vuam-kev sib txuas

Kev tuav arc vuam yog qhia hauv daim duab:

Ua ntej welding, txuas lub welded workpiece thiab vuam vuam mus rau ob tug ncej ntawm lub tshuab hluav taws xob welding thiab clamp lub vuam pas nrig nrog lub vuam tongs.Thaum lub sij hawm vuam, vuam pas nrig thiab lub workpiece yog nyob rau hauv instantaneous sib cuag, tsim ib tug luv luv Circuit Court, thiab ces lawv sib cais los ntawm ib tug tej yam deb (kwv yees li 2-4 hli), thiab lub arc yog ignited.

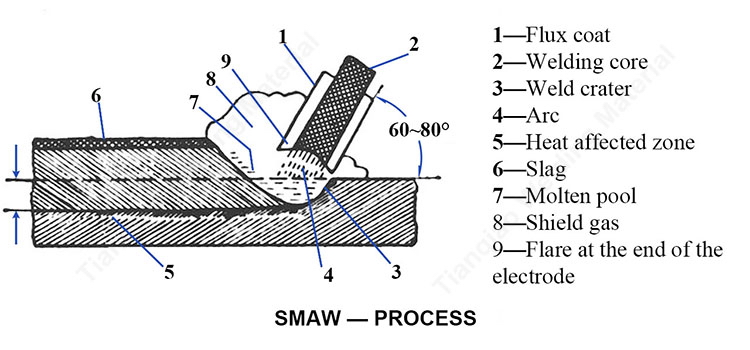

Daim duab 2: Shielded Hlau Arc Vuam- txheej txheem

Lub workpiece nyob rau hauv lub arc tam sim ntawd melts los ua ib tug semi-oval molten pas dej ua ke.Tom qab cov txheej txheej electrode yog yaj, ib feem ntawm nws dhau los ua cov pa roj uas nyob ib puag ncig lub arc kom cais tawm ntawm huab cua, yog li tiv thaiv cov kua hlau los ntawm oxygen thiab nitrogen;ib feem ntawm nws ua molten slag, los yog sprayed rau hauv lub pas dej ua ke molten ib leeg, los yog melted nrog cov tub ntxhais Lub molten droplets ntawm kua hlau yog sprayed mus rau lub molten pas dej ua ke.

Nyob rau hauv lub arc thiab molten pas dej ua ke, cov kua hlau, slag thiab arc gas yuav raug ib tug tej yam kev hloov ntawm lub cev thiab tshuaj, xws li dissolution ntawm cov roj rau hauv cov kua hlau thiab oxidation-txo cov tshuaj tiv thaiv.Cov pa roj thiab slag nyob rau hauv lub pas dej molten ntab vim nws lub teeb yuag.Thaum lub arc raug tshem tawm, qhov kub thiab txias poob thiab cov hlau thiab slag yuav solidify ib tom qab.Nyob rau hauv txoj kev no, ob daim hlau yog koom nrog melted thiab crystallized weld hlau.Vim hais tias lub shrinkage ntawm slag yog txawv ntawm cov hlau, nws yuav plam ntawm lub slag plhaub thiab cov hlau ciam teb, thiab lub slag plhaub tej zaum yuav poob tawm, los yog poob tawm tom qab raug khob, thiab hlau weld seam nrog ntses nplai. tuaj yeem raug nthuav tawm.

Cov khoom tseem ceeb ntawm phau ntawv arc vuam yog hluav taws xob vuam tshuab.Lub tshuab hluav taws xob vuam yog lub zog hluav taws xob uas tsim cov vuam arc, thiab muaj ob hom AC thiab DC.Tam sim no, muaj ntau hom hluav taws xob vuam tshuab tsim nyob rau hauv Suav teb, uas tuaj yeem muab faib ua AC hluav taws xob vuam tshuab thiab DC hluav taws xob vuam tshuab raws li lawv cov qauv.

Muaj ob txoj hauv kev sib txawv rau DC vuam tshuab.Thaum lub electrode txuas nrog qhov tsis zoo electrode thiab lub workpiece txuas nrog qhov zoo electrode, nws yog txoj kev sib txuas zoo;qhov opposite yog txoj kev txuas rov qab.Feem ntau, thaum vuam nrog alkaline qis-hydrogen electrode (xws liua 7018, ua 7016), txhawm rau ua kom cov arc hlawv ruaj khov, nws tau teev tseg kom siv DC thim rov qab txoj kev sib txuas;thaum siv cov kua qaub electrode (xws liE6013, j422 ua) rau weld tuab steel daim hlau, txoj kev sib txuas rau pem hauv ntej yog siv, vim hais tias qhov anode qhov kub siab tshaj qhov cathode, thiab txoj kev sib txuas rau pem hauv ntej tuaj yeem tau txais qhov tob tob tob;Thaum welding nyias steel daim hlau thiab cov hlau tsis muaj hlau, txoj kev rov qab txuas yog siv.Thaum welding nrog alternating tam sim no, txij li thaum lub polarity hloov pauv, tsis tas yuav xaiv qhov sib txuas polarity.

Cov khoom siv welding rau phau ntawv vuam yog ib qho hluav taws xob vuam pas nrig, uas muaj cov tub ntxhais hlau thiab txheej txheej sab nraud ntawm cov tub ntxhais hlau (tseem saibQhov muaj pes tsawg leeg ntawm vuam electrode).

Vuam core

Lub luag haujlwm ntawm cov tub ntxhais hlau (welding core) feem ntau yog los ua hluav taws xob thiab tsim cov hlau tso nrog ib qho muaj pes tsawg leeg ntawm qhov kawg ntawm cov electrode.Lub vuam core tuaj yeem ua los ntawm ntau yam hlau.Qhov muaj pes tsawg leeg ntawm cov welding core ncaj qha cuam tshuam qhov muaj pes tsawg leeg thiab kev ua tau zoo ntawm cov hlau tso.Yog li ntawd, cov tub ntxhais vuam yuav tsum tau txo qis cov ntsiab lus ntawm cov teeb meem.Ntxiv rau qhov txwv tsis pub S thiab P, qee qhov vuam rods xav tau cov tub ntxhais vuam los tswj As, Sb, Sn thiab lwm yam.

Daim duab 3: Tianqiao vuam electrode E6013

Flux lub tsho

Electrode txheej kuj tseem hu ua xim.Lub hom phiaj tseem ceeb ntawm txheej txheej ntawm cov tub ntxhais yog los pab txhawb kev ua haujlwm vuam thiab xyuas kom meej tias cov hlau tso rau hauv cov khoom muaj qee yam muaj pes tsawg leeg thiab kev ua haujlwm.Electrode coatings tuaj yeem sib xyaw nrog ntau pua cov khoom siv hmoov xws li oxides, carbonates, silicates, organics, fluorides, ferroalloys thiab cov khoom siv tshuaj raws li ib qho piv txwv.Ntau yam khoom siv raw tuaj yeem muab faib ua pawg hauv qab no raws li lawv lub luag haujlwm hauv electrode txheej:

1. Stabilizer ua rau cov electrode yooj yim pib lub arc thiab tuaj yeem ua kom cov arc hlawv ruaj khov thaum lub sijhawm vuam.Txhua yam khoom uas yooj yim rau ionize tuaj yeem txhim kho qhov arc.Feem ntau, cov tebchaw ntawm alkali hlau thiab alkaline ntiaj teb hlau, xws li potassium carbonate, sodium carbonate, marble, thiab lwm yam, yog siv.

2. Slag-forming tus neeg sawv cev tuaj yeem tsim cov molten slag nrog qee yam khoom siv lub cev thiab tshuaj lom neeg thaum lub sij hawm vuam, npog qhov saum npoo ntawm cov hlau molten, tiv thaiv lub pas dej welding thiab txhim kho cov duab ntawm cov vuam.

3. Deoxidizer los ntawm cov tshuaj metallurgical cov tshuaj tiv thaiv hauv cov txheej txheem vuam kom txo cov pa oxygen hauv cov hlau vuam thiab txhim kho cov khoom siv ntawm cov vuam.Lub ntsiab deoxidizers yog ferromanganese, ferrosilicon, thiab ferro-titanium.

4. Gas generating tus neeg sawv cev tuaj yeem cais thiab tso cov pa roj raws li qhov kev txiav txim ntawm arc siab kub los tiv thaiv lub pas dej arc thiab molten thiab tiv thaiv kev nkag mus ntawm oxygen thiab nitrogen nyob rau hauv ib puag ncig huab cua.

5. Tus neeg sawv cev Alloying Nws yog siv los them nyiaj rau kev kub hnyiab ntawm cov hlau alloy thiab kev hloov pauv ntawm cov ntsiab lus alloy mus rau qhov vuam thaum lub sij hawm vuam txheej txheem los xyuas kom meej tias cov hlau vuam tau txais cov tshuaj tsim nyog thiab kev ua haujlwm.

6. Plasticizing Lubricant Ua kom cov plasticity, slippage thiab fluidity ntawm cov hmoov txheej hauv cov txheej txheem vuam pas nrig txhawm rau txhim kho cov nias zoo ntawm cov vuam pas nrig thiab txo cov eccentricity.

7. Adhesives Ua kom cov hmoov txheej txheej muaj qee qhov viscosity thaum lub sijhawm txheej txheej txheej txheej txheej, tuaj yeem ruaj khov nrog cov tub ntxhais vuam, thiab ua kom cov vuam pas nrig txheej muaj qee lub zog tom qab ziab.

Post lub sij hawm: Lub Xya hli ntuj-27-2021