Vuam electrode yog ib tug hlau pas nrig uas yog melted thiab sau nyob rau hauv lub sib koom tes ntawm lub vuam workpiece thaum lub sij hawm roj vuam los yog hluav taws xob welding.Cov khoom siv ntawm cov electrode feem ntau yog tib yam li cov khoom ntawm cov khoom ua haujlwm.

Ntawm no peb tuaj nkag siab yuav ua li cas nrog vuam electrode yog tsim los ntawm:

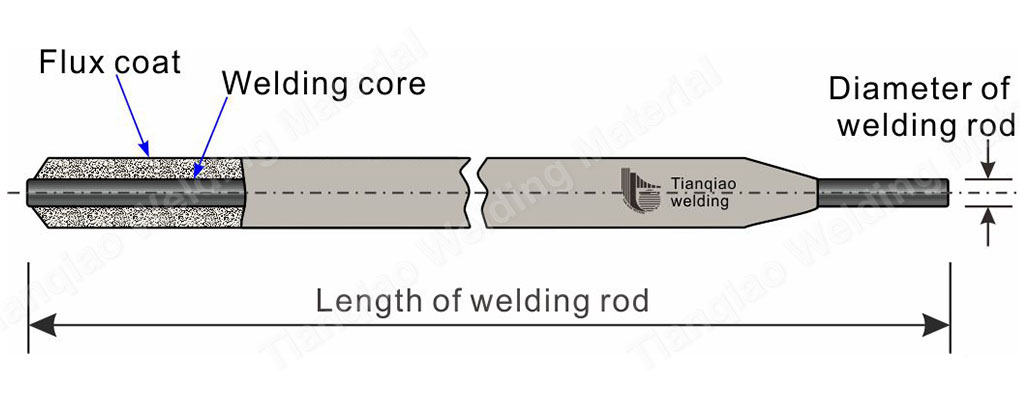

Daim duab 1 Cov qauv ntawm Tianqiao vuam electrode

Lub vuam electrode yog ib qho hluav taws xob melting electrode coated nrog ib txheej rau arc vuam ntawm vuam pas nrig.Nws yog tsim los ntawm txheej txheej thiab vuam core.

Cov tub ntxhais hlau npog los ntawm txheej txheej hauv lub vuam pas nrig yog hu uavuam core.Cov tub ntxhais vuam feem ntau yog cov hlau hlau uas muaj qhov ntev thiab txoj kab uas hla.

Daim duab 2 Tub ntxhais ntawm Tianqiao vuam electrode

Ob txoj haujlwm ntawm lub hauv paus

1. Ua cov vuam tam sim no thiab tsim cov arc hloov hluav taws xob rau hauv cov cua sov.

2. Lub vuam core nws tus kheej melts raws li ib tug muab tub lim hlau thiab fuses nrog cov kua hauv paus hlau los ua ib tug weld.Thaum welding nrog ib qho electrode, cov hlau tseem ceeb yog ib feem ntawm tag nrho cov hlau weld.Yog li ntawd, cov tshuaj muaj pes tsawg leeg ntawm cov tub ntxhais weld ncaj qha cuam tshuam qhov zoo ntawm cov vuam.Yog li ntawd, cov hlau hlau siv los ua cov tub ntxhais ntawm cov electrode muaj nws hom thiab muaj pes tsawg leeg cais.

Electrode txheejhais txog cov txheej txheej uas siv rau ntawm qhov chaw ntawm lub vuam core.Cov txheej yog decomposed thiab melted nyob rau hauv cov txheej txheem vuam los tsim cov roj thiab slag, uas ua lub luag haujlwm hauv kev tiv thaiv kev siv tshuab, kev kho metallurgical, thiab txhim kho cov txheej txheem kev ua haujlwm.

Daim duab 3 Txheej ntawm Tianqiao vuam electrode

Cov txheej txheem muaj xws li: minerals (xws li marble, fluorspar, thiab lwm yam), ferroalloys thiab hlau hmoov (xws li ferromanganese, ferro-titanium, thiab lwm yam), organic tshuaj (xws li ntoo hmoov, cellulose, thiab lwm yam), Cov khoom siv tshuaj (xws li titanium dioxide, iav dej, thiab lwm yam).Electrode txheej yog qhov tseem ceeb hauv kev txiav txim siab qhov zoo ntawm welds.

Lub luag haujlwm tseem ceeb ntawm txheej txheej hauv cov txheej txheem vuam

1. Txhim kho qhov ruaj khov ntawm arc combustion:

Lub uncoated electrode tsis yooj yim rau ignite lub arc.Txawm hais tias nws yog ignited, nws tsis tuaj yeem hlawv ruaj khov.

2. Tiv thaiv lub pas dej ua ke:

Thaum lub sij hawm vuam txheej txheem, oxygen, nitrogen thiab dej vapor nyob rau hauv cov huab cua nkag mus rau hauv lub weld seam, uas yuav muaj kev cuam tshuam tsis zoo rau lub weld seam.Tsis tsuas yog tsim ntawm pores, tab sis kuj txo cov neeg kho tshuab zog ntawm weld, thiab txawm ua rau tawg.Tom qab cov txheej electrode melted, ib tug loj npaum li cas ntawm cov roj yog generated npog lub arc thiab molten pas dej ua ke, uas yuav txo tau cov kev sib tshuam ntawm cov hlau molten thiab huab cua.Thaum cov weld txias, cov txheej txheej melted tsim ib txheej ntawm slag, uas npog qhov chaw ntawm lub vuam, tiv thaiv cov hlau vuam thiab txias nws maj mam, txo qhov muaj peev xwm ntawm porosity.

Peb, kom ntseeg tau tias cov vuam yog deoxidized thiab desulfurized thiab phosphorus impurities

Txawm hais tias kev tiv thaiv yog nqa tawm thaum lub sij hawm vuam, nws tseem yog ib qho tseem ceeb uas cov pa me me yuav nkag mus rau hauv lub pas dej molten kom oxidize cov hlau thiab hlau, hlawv cov hlau alloy, thiab txo qhov zoo ntawm cov vuam.Yog li ntawd, nws yog ib qho tsim nyog yuav tsum tau ntxiv cov tshuaj txo qis (xws li manganese, silicon, titanium, aluminium, thiab lwm yam) rau cov txheej txheem electrode kom txo cov oxides uas tau nkag mus rau hauv lub pas dej molten.

4. Ntxiv alloying ntsiab rau lub vuam:

Vim muaj qhov kub thiab txias ntawm cov arc, cov alloying ntsiab ntawm cov hlau weld yuav evaporated thiab burnt, uas yuav txo tau cov mechanical zog ntawm weld.Yog li ntawd, nws yog ib qho tsim nyog yuav tsum tau ntxiv cov ntsiab lus alloying tsim nyog rau lub vuam los ntawm cov txheej txheem kom them nyiaj rau qhov kub hnyiab ntawm cov ntsiab lus alloy thiab kom ntseeg tau lossis txhim kho cov khoom siv ntawm cov khoom siv vuam.Rau kev vuam ntawm qee cov hlau alloy, nws tseem yuav tsum tau nkag mus rau hauv cov hlau rau hauv cov vuam los ntawm txheej, kom cov hlau vuam tuaj yeem nyob ze rau cov hlau muaj pes tsawg leeg ntawm cov hlau hauv paus, thiab cov khoom siv kho tshuab tuaj yeem ntes los yog ntau tshaj. lub hauv paus hlau.

5. Txhim kho vuam kev tsim khoom thiab txo qhov tawg:

Cov txheej txheej electrode muaj cov nyhuv ntawm kev ua kom cov tee dej thiab txo cov spatter.Lub melting point ntawm electrode txheej yog me ntsis qis dua qhov vuam taw tes ntawm cov tub ntxhais.Txawm li cas los xij, vim tias cov tub ntxhais vuam yog nyob rau hauv nruab nrab ntawm lub arc thiab qhov kub thiab txias yog qhov siab, qhov vuam core melts ua ntej, thiab txheej txheej melts me ntsis tom qab.Nyob rau tib lub sijhawm, txij li cov hlau tsis tau tshwm sim los ntawm kev sib tsoo yog txo, qhov kev tso nyiaj coefficient nce ntxiv, thiab cov khoom siv vuam kuj tseem txhim kho.

Post lub sij hawm: Jun-01-2021