Lub npe hu ua vuam txuj ci yog txoj kev vuam yooj yim, lub kaum sab xis electrode thiab kev ua haujlwm, thiab koj cov welds yuav tsis phem heev.

Thaum pib ntawm vuam, vim tsis muaj kev txawj ntse ntawm cov vuam sib dhos thiab cov txheej txheem tuav tsis tau zoo, nws yuav ua rau nres.Yog tias nws tob dua thiab ntiav, nws yuav yooj yim ua rau lub qhov hws, Kev Sau ntawv zoo ib yam, mob stroke los ntawm stroke.

Ntau yam tsis xws luag ntawm welding:

1. Sab nraud undercut

Vuam txheej txheem parameter xaiv tsis raug lossis kev ua haujlwm tsis yog tus qauv, vuam raws lub hauv paus hlau qhov chaw ntawm kev tsim cov zawj lossis kev nyuaj siab, hu ua tom ntug.(Thaum pib vuam vim tsis paub qhov luaj li cas ntawm qhov tam sim no thiab vuam tes tsis ruaj khov yog ib qho yooj yim ua rau tom, tiv thaiv kev sib tsoo yog xyaum vuam cov txheej txheem, yuav tsum ruaj khov, tsis txhob txhawj.)

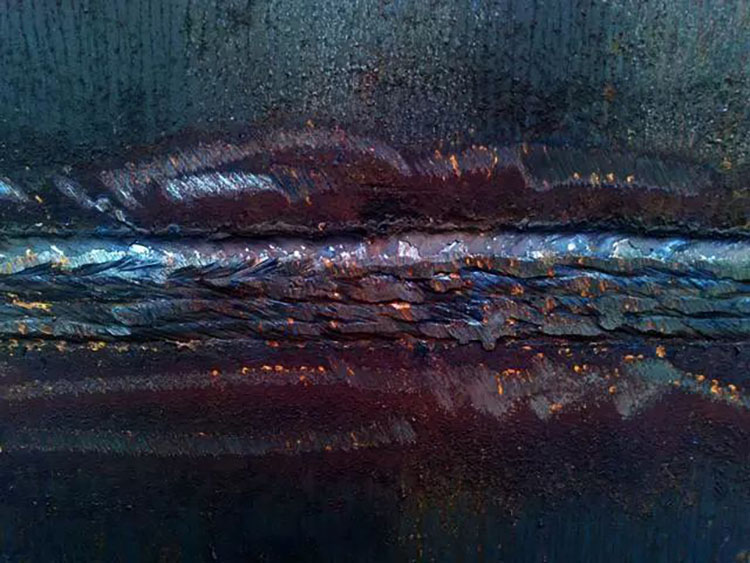

Qhov no yog ib daim duab ntawm lub undercut

2. Lub plab

Thaum lub sij hawm vuam, cov pa roj hauv lub pas dej molten tsis khiav tawm thaum nws solidifies thiab tseem nyob rau hauv lub vuam los tsim ib kab noj hniav, uas yog hu ua ib tug porosity.(Thaum pib vuam, vim tsis muaj peev xwm tuav lub vuam sib dhos thiab kev tuav tsis zoo ntawm cov strips, nws yuav ua rau nres. Yog tias nws tob dua thiab ntiav, nws yuav yooj yim ua rau qhov pores. stroke ntawm ib lub sijhawm.)

Qhov no yog lub qhov cua ntawm qhov vuam

3.Tsis nkag mus, tsis fused

Muaj ntau qhov laj thawj rau kev nkag mus tsis tiav thiab infusion, xws li me me qhov sib txawv ntawm qhov sib txawv los yog qhov zawj lub kaum ntse ntse, tuab tuab heev, txoj kab uas hla ntawm electrode loj heev, vuam ceev heev los yog ntev arc, thiab lwm yam. cuam tshuam los ntawm impurities nyob rau hauv qhov zawj, thiab unmelted impurities kuj yuav cuam tshuam rau fusion nyhuv ntawm weld.

(Tsuas yog tswj lub vuam ceev, tam sim no thiab lwm yam txheej txheem tsis tau thaum lub vuam, xaiv qhov zawj kom raug, thiab tshem tawm cov nplai thiab impurities ntawm qhov zawj; lub hauv paus ntawm lub nraub qaum vuam yuav tsum tau muab ntxuav kom huv.)

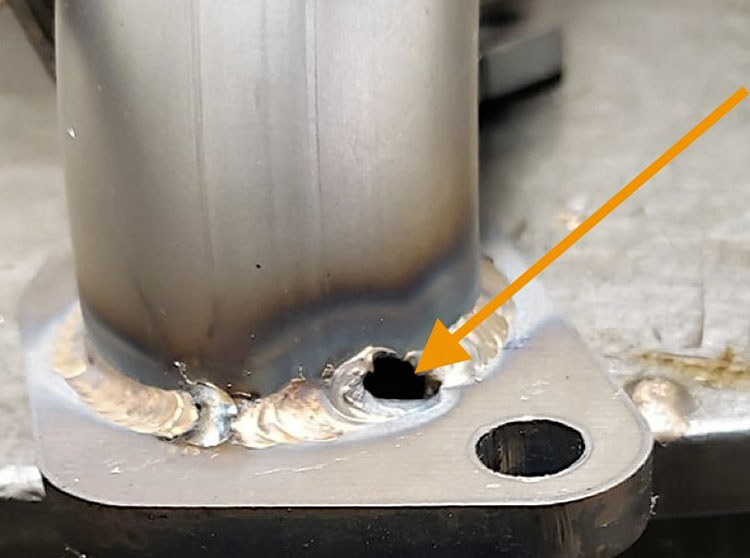

Kev nkag tsis tiav

4. Hlawv dhau

Thaum lub sij hawm vuam txheej txheem, cov hlau molten ntws tawm ntawm lub nraub qaum ntawm qhov zawj, tsim ib qho kev tsis xws luag hu ua hlawv-dhau.(Txoj kev tiv thaiv yog txhawm rau txo qhov tam sim no thiab txo qhov sib txawv ntawm qhov vuam)

Vuam duab hlawv dhau

5.Unsightly vuam nto

Cov teeb meem xws li lapping thiab serpentine hlaws yog txhua yam tshwm sim los ntawm kev sib tsoo qeeb dhau thiab vuam tam sim no tsawg dhau.(Txoj hauv kev tiv thaiv nws yog kev xyaum ntau dua thiab tuav qhov tsim nyog vuam ceev. Cov neeg feem coob yuav ua qhov no thaum pib, xyaum ntau dua.)

Serpentine vuam

lap vuam

Post lub sij hawm: May-31-2023