Qhov kev thov rau steel nyob rau hauv niaj hnub haiv neeg yog tas li nce.Hauv lub neej niaj hnub, ntau yam yog ua los ntawm hlau, thiab ntau cov hlau tsis tuaj yeem raug pov rau tib lub sijhawm.Yog li ntawd, nws yog ib qho tsim nyog yuav tau siv hluav taws xob vuam rau vuam.Lub luag haujlwm ntawm electrode hauv cov txheej txheem vuam hluav taws xob yog qhov tseem ceeb heev.

Lub vuam pas nrig yog energized thiab melted ntawm kub thaum lub sij hawm arc vuam, thiab nyob rau hauv cov pob qij txha ntawm lub vuam workpiece.Feem ntau, cov khoom siv electrode raug xaiv raws li cov khoom siv ntawm vuam workpiece.Vuam pas nrig tuaj yeem siv rau vuam tib yam hlau lossis vuam ntawm cov hlau sib txawv.

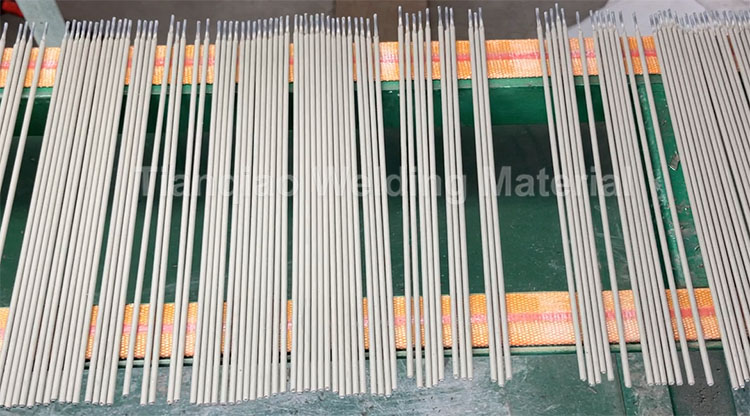

Structure ntawm Vuam Electrode

Internal hlau core ntawm vuam pas nrig thiab sab nrauv txheej yog tsim.Lub welding core yog steel hlau nrog ib txoj kab uas hla thiab ntev.Lub luag haujlwm tseem ceeb ntawm cov tub ntxhais vuam yog ua tam sim no kom sov thiab yaj, thiab sau thiab txuas lub workpiece.

Cov khoom siv tseem ceeb siv rau vuam feem ntau tuaj yeem muab faib ua carbon steel, alloy steel thiab stainless hlau.Txawm li cas los xij, txhawm rau ua kom tau raws li qhov yuav tsum tau ua ntawm vuam, muaj cov kev cai tshwj xeeb rau cov khoom siv thiab cov hlau ntawm cov tub ntxhais vuam, thiab muaj cov kev cai nruj ntawm cov ntsiab lus ntawm qee cov hlau.Vim tias cov hlau muaj pes tsawg leeg ntawm cov tub ntxhais vuam yuav cuam tshuam ncaj qha rau qhov zoo ntawm cov vuam.

Yuav muaj txheej txheej txheej sab nraud ntawm electrode, uas yog hu ua flux coat.Flux coat plays lub luag haujlwm tseem ceeb.Yog hais tias lub welding core yog siv los txuas ncaj qha rau qhov chaw ua haujlwm, huab cua thiab lwm yam khoom yuav nkag mus rau hauv cov hlau molten ntawm lub tshuab hluav taws xob vuam, thiab cov tshuaj tiv thaiv yuav tshwm sim hauv cov hlau molten ncaj qha rau qhov vuam.Cov teeb meem zoo xws li qhov hws thiab tawg yuav cuam tshuam rau lub zog vuam.Flux lub tsho uas muaj cov ntsiab lus tshwj xeeb yuav decompose thiab yaj rau hauv cov pa roj thiab slag ntawm qhov kub thiab txias, uas tuaj yeem tiv thaiv huab cua los ntawm kev nkag mus thiab txhim kho vuam zoo.

Cov khoom xyaw ntawm lub tsho tiv no muaj xws li: hydrochloric acid, fluoride, carbonate, oxide, organic teeb meem, hlau alloy thiab lwm yam tshuaj hmoov, thiab lwm yam., sib tov raws li ib tug tej yam formula ratio.Cov txheej txheem ntawm ntau hom electrode coatings kuj txawv.

Muaj peb hom, xws li slag tus neeg sawv cev, cov khoom tsim hluav taws xob, thiab deoxidizer.

Tus neeg sawv cev slag yog cov khoom sib xyaw uas tuaj yeem tiv thaiv cov hlau molten los ntawm huab cua ingress thaum lub electrode melted, yog li txhim kho qhov zoo ntawm vuam.

Cov roj tsim hluav taws xob yog tsim los ntawm cov hmoov txhuv nplej siab thiab ntoo hmoov thiab lwm yam tshuaj, uas muaj qee qhov kev txo qis.

Lub deoxidizer yog tsim los ntawm ferro-titanium thiab ferromanganese.Feem ntau, cov khoom no tuaj yeem txhim kho qhov hnav tsis kam thiab corrosion kuj ntawm cov hlau.

Tsis tas li ntawd, muaj lwm yam txheej txheej ntawm electrode nto, thiab qhov sib xyaw thiab qhov sib piv ntawm txhua hom yuav txawv.

Kev tsim cov txheej txheem ntawm vuam electrode

Kev tsim cov txheej txheem ntawm vuam pas nrig yog tsim cov vuam core thiab npaj cov txheej txheem raws li qhov tsim nyog ntawm cov vuam pas nrig, thiab siv cov txheej txheem sib npaug ntawm cov tub ntxhais vuam kom ua tau raws li qhov tsim nyog ntawm cov vuam pas nrig.

Ua ntej, lub dov steel bar yog rub tawm ntawm lub coiler, cov xeb ntawm qhov chaw ntawm lub steel bar raug tshem tawm nyob rau hauv lub tshuab, thiab ces nws yog straightened.Lub tshuab txiav steel bar rau qhov ntev ntawm cov electrode.

Tom ntej no, ib txheej yuav tsum tau npaj rau saum npoo ntawm electrode.Ntau yam khoom siv raw ntawm txheej yog sieved kom tshem tawm cov impurities, thiab tom qab ntawd nchuav rau hauv lub tshuab raws li qhov kev faib ua feem, thiab cov binder ntxiv rau tib lub sijhawm.Tag nrho cov hmoov raw khoom yog sib xyaw kom huv si los ntawm kev ntxhov siab ntawm lub tshuab.

Muab cov hmoov sib tov rau hauv pwm thiab nias rau hauv lub cylindrical lub tog raj kheej nrog ib lub voj voog nyob hauv nruab nrab.

Muab cov nias ntau lub thoob rau hauv lub tshuab, muab cov welding cores huv si rau hauv lub tshuab pub chaw nres nkoj, cov vuam cores nkag mus rau hauv lub tshuab los ntawm lub tshuab pub chaw nres nkoj, thiab cov welding cores dhau los ntawm nruab nrab ntawm lub thoob vim extrusion.Lub tshuab sib npaug sib kis cov hmoov ntawm cov tub ntxhais hla dhau los ua txheej txheej.

Thaum lub sij hawm txheej txheej ntawm vuam pas nrig, tag nrho cov welding core yog coated nrog ib txheej ntawm txheej.Txhawm rau ua kom cov electrode yooj yim rau clamp thiab ua hluav taws xob, lub taub hau thiab tus Tsov tus tw ntawm cov electrode yuav tsum tau polished tawm ntawm txheej kom nthuav tawm cov tub ntxhais vuam.

Tom qab txheej txheej yog thov, lub taub hau sib tsoo thiab vuam pas nrig tom qab sib tsoo tus Tsov tus tw yuav sib npaug ntawm cov hlau ncej thiab xa mus rau qhov cub kom qhuav.

Txhawm rau kom yooj yim paub qhov txawv ntawm cov qauv thiab cov qauv ntawm cov electrode, nws yog ib qho tsim nyog yuav tau luam tawm ntawm cov electrode.Thaum lub vuam pas nrig txav ntawm txoj siv conveyor, txhua lub electrode yog luam tawm los ntawm cov roj hmab luam ntawv rau ntawm txoj siv conveyor.

Tom qab lub vuam pas nrig qauv luam tawm, lub vuam pas nrig tuaj yeem ntim thiab muag tom qab dhau qhov kev tshuaj xyuas.

Tianqiao hom vuam electrodes muaj kev ua tau zoo, ruaj khov zoo, zoo nkauj vuam molding, thiab zoo slag tshem tawm, muaj peev xwm tiv taus xeb, Stomata thiab tawg, zoo thiab ruaj khov deposited hlau mechanics cim.Tianqiao hom vuam cov ntaub ntawv ua tau raws li cov neeg siv khoom zoo siab txais tos vim qhov zoo tshaj plaws, kev ua tau zoo thiab cov nqi sib tw.Nyem qhov nomus saib ntxiv txog peb cov khoom

Post lub sij hawm: Sep-03-2021