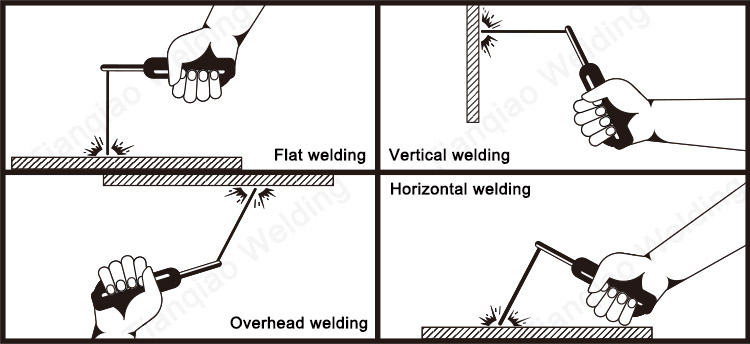

Lub vuam txoj hauj lwm yog xa mus rau thaum vuam, tus txheeb ze spatial txoj hauj lwm ntawm lub vuam mus rau welder.

Daim duab 1. Tianqiao vuam positon

Daim duab 1. Tianqiao vuam positon

Muaj welding tiaj tus, kab rov tav vuam, ntsug vuam thiab nyiaj siv ua haujlwm vuam.Pav ca vuam yog hais txog kab rov tav vuam ua los ntawm cov vuam nyo hau nws lub taub hau, yog li nws tseem hu ua downhand welding;rau qhov sib txuas ntawm T-zoo li tus, T-shaped weldment feem ntau muab tso rau ntawm 45 ° los ua qhov vuam txoj hauj lwm ntawm downward vuam seam, thiaj li hu ua nkoj vuam.Kab rov tav vuam yog hais txog kab rov tav vuam ua los ntawm tus welder ntawm kwv yees li qhov siab tib yam li ntawm caj npab.Vertical welding yog hais txog lub hauv qab-up ntsug vuam los ntawm tus welder.Overhead welding yog hais txog kab rov tav seam welding ua los ntawm welder ntsia.Lub vuam vuam yog qhov yooj yim tshaj plaws los xyuas kom meej qhov vuam zoo, kab rov tav vuam yog qhov thib ob, ntsug vuam yog qhov thib peb, thiab vuam siv lub taub hau yog qhov nyuaj tshaj plaws los xyuas kom zoo thiab yuav tsum zam kom ntau li ntau tau.

Daim duab 2. Tianqiao tiaj vuam

Daim duab 2. Tianqiao tiaj vuam

Vuam tiaj

Welding yam ntxwv ntawm tiaj welding:

1. Lub vuam hlau feem ntau yog nyob ntawm nws tus kheej qhov hnyav kom hloov mus rau lub pas dej molten.

2. Cov duab thiab hlau ntawm lub pas dej molten yog yooj yim los tswj thiab tswj.

3. Rau vuam hlau nrog tib lub thickness, vuam tam sim no nyob rau hauv lub tiaj vuam txoj hauj lwm yog loj dua li nyob rau hauv lwm yam vuam txoj hauj lwm, thiab cov efficiency ntau lawm.

4. Cov slag thiab molten pas dej ua ke yog nquag sib tov, tshwj xeeb tshaj yog thaum welding ca fillet welds, lub slag yog ib qho yooj yim rau txhuas thiab daim ntawv slag inclusion.

* Nws tsis yooj yim kom paub qhov txawv ntawm slag ntawm acid vuam pas nrig los ntawm lub pas dej molten;ob ntawm alkaline vuam pas nrig yog qhov tseeb;HG20581 tus qauv qhia meej meej tias cov pas nrig vuam tsis tuaj yeem siv rau hauv cov hlab ntsha II thiab III.

5. Kev siv vuam tsis raug thiab kev ua haujlwm tau yooj yim tuaj yeem ua rau muaj qhov tsis xws luag xws li cov hlaws hlaws, hlais, thiab vuam deformation.

6. Thaum sab nraub qaum ntawm ib leeg-sab vuam yog tsim los ntawm kev ywj pheej, thawj qhov vuam yog ua rau cov txheej txheem nkag mus tsis sib xws thiab tsis zoo rov qab molding.

Cov ntsiab lus ntawm welding tiaj tus:

1. Raws li lub thickness ntawm lub phaj, ib txoj kab uas hla loj electrode thiab ib tug loj vuam tam sim no yuav siv tau.

2. Thaum vuam, vuam pas nrig thiab vuam ua ib lub kaum sab xis ntawm 60 ~ 80 °, thiab kev sib cais ntawm slag thiab kua hlau yog tswj los tiv thaiv cov slag los ntawm kev tshwm sim ua ntej.

3. Thaum lub phaj thickness tsawg dua los yog sib npaug li 6 hli, lub taub qab tiaj vuam feem ntau muaj hom kuv zawj, thiab cov vuam vuam pem hauv ntej yuav tsum yog luv-arc vuam nrog lub φ3.2 ~ 4 electrode, thiab qhov tob tob tuaj yeem ncav cuag 2/3 ntawm lub phaj thickness;ua ntej lub nraub qaum yog kaw, Nws tsis tas yuav tsum tau ntxuav cov hauv paus hniav (tshwj tsis yog cov qauv tseem ceeb), tab sis cov slag yuav tsum tau muab ntxuav thiab tam sim no tuaj yeem loj dua.

4. Yog tias tsis muaj qhov sib xyaw ntawm cov slag thiab molten pas hlau hlau hauv lub taub qab vuam, lub arc tuaj yeem elongated, cov electrode tuaj yeem tig mus rau pem hauv ntej, thiab cov slag molten tuaj yeem raug thawb mus rau sab nraum qab ntawm lub pas dej molten kom tiv thaiv slag suav nrog.

5. Thaum welding horizontally inclined welds, upslope welding yuav tsum tau siv los tiv thaiv slag inclusion thiab molten pas dej ua ke los mus rau pem hauv ntej kom tsis txhob slag inclusion.

6. Thaum siv cov txheej txheem ntau thiab ntau qhov kev sib txuas, ua tib zoo saib xyuas cov txheej txheem vuam thiab vuam ib ntus, thiab txhua txheej yuav tsum tsis pub tshaj 4 ~ 5 hli.

7. Rau lub kaum sab xis welded pob qij txha ntawm T hom, kaum sib koom ua ke, thiab sib tshooj sib koom ua ke, yog tias lub thickness ntawm ob daim hlau sib txawv, lub kaum sab xis ntawm vuam pas nrig yuav tsum tau kho kom deflect lub arc mus rau ib sab ntawm cov phaj tuab, thiaj li hais tias ob daim hlau yog rhuab sib npaug.

8. Qhov raug xaiv ntawm shipping txoj kev

(1) Thaum vuam thickness tsawg dua los yog sib npaug li 6 hli, hom kuv zawj pob tw tiaj vuam.Thaum ob tog welding yog saws, pem hauv ntej vuam seam txais ib txoj kab ncaj nraim, uas yog me ntsis qeeb;rov qab vuam seam kuj txais ib txoj kab ncaj nraim, thiab cov vuam tam sim no me ntsis loj dua., Ceev dua.

(2) Thaum lub thickness ntawm lub phaj yog ≤6 hli, thaum qhib lwm cov ntaub ntawv ntawm grooves, multi-txheej vuam los yog multi-txheej multi-pass vuam siv tau.Thawj txheej ntawm cov vuam hauv qab yuav tsum siv cov electrode me me tam sim no, cov qauv me me tam sim no, txoj kab ncaj nraim los yog sawtooth.Puab thauj bar vuam.Rau kev txhaws txheej vuam, ib txoj kab uas hla loj dua electrode thiab luv arc vuam nrog cov vuam tam sim no loj tuaj yeem xaiv tau.

(3) Thaum qhov loj ntawm cov ceg ntawm lub tiaj tiaj tiaj vuam ntawm T-joint yog tsawg dua 6 hli, ib txheej txheej vuam tuaj yeem siv tau, thiab siv txoj hlua linear, oblique los yog zigzag-zoo li tus qauv thauj;Thaum qhov loj ntawm cov ceg loj dua, yuav tsum siv ntau txheej vuam lossis ntau txheej vuam yuav tsum tau siv.Multi-pass welding, hauv qab vuam siv txoj kev tsheb thauj mus los, thiab txheej txheej tuaj yeem xaiv oblique sawtooth lossis oblique ncig sawb tsheb thauj mus los.

(4) Feem ntau, ntau txheej thiab ntau dhau vuam yuav tsum tau welded los ntawm txoj kab ncaj nraim.

Me me hlau electrodes haum rau tiaj vuam yogAWS E6013, AWS E6010, AWS E6011, AWS E7018.

Daim duab 3. Tianqiao ntsug vuam

Daim duab 3. Tianqiao ntsug vuam

Vertical vuam

Vuam cov yam ntxwv ntawm ntsug welding:

1. Lub pas dej molten hlau thiab molten slag poob vim lawv qhov hnyav thiab yooj yim rau kev sib cais.

2. Thaum qhov kub ntawm lub pas dej molten siab dhau lawm, lub pas dej molten hlau yog ib qho yooj yim rau drip los ua qhov tsis xws luag xws li weld hlaws, undercut, slag inclusion, thiab lwm yam, thiab cov weld tsis sib xws.

3. Lub hauv paus ntawm T-joint weld yog ib qho yooj yim rau kev nkag mus tsis tiav.

4. Lub degree ntawm kev nkag mus yog yooj yim los tuav.

5. Welding productivity yog qis dua tiaj vuam.

Lub ntsiab ntsiab lus ntawm ntsug welding:

1. Khaws lub kaum sab xis vuam kom raug;

2. Nyob rau hauv ntau lawm, ntsug welding feem ntau yog siv, thiab ntsug ntsug vuam yuav tsum tau tshwj xeeb vuam rods los xyuas kom meej qhov zoo ntawm cov vuam.Lub vuam tam sim no rau ntsug welding yog 10 ~ 15% me dua li ntawd rau cov vuam tiaj tus, thiab ib txoj kab uas hla me electrode (<φ4mm) yuav tsum tau xaiv.

3. Siv luv arc vuam kom luv qhov kev ncua deb ntawm cov tee dej mus rau lub pas dej molten.

4. Siv txoj kev xa khoom kom raug.

(1) T-groove pob tw pob qij txha (feem ntau yog siv rau nyias daim hlau) thaum ntsug vuam yog ua, linear, zigzag, crescent-shaped sawb vuam feem ntau yog siv, thiab qhov siab tshaj plaws arc ntev tsis ntau tshaj 6 hli.

(2) Thaum qhib lwm cov ntaub ntawv ntawm zawj pob tw ntsug vuam, thawj txheej ntawm vuam feem ntau welded los ntawm tawg, crescent-puab thiab daim duab peb sab-shaped sawb vuam nrog lub viav vias me.Tom qab ntawd, txhua txheej tuaj yeem siv rau crescent lossis zigzag striping.

(3) Thaum lub sijhawm vuam ntsug ntawm T-zoo li cov pob qij txha, lub vuam pas nrig yuav tsum muaj lub sijhawm nyob ntawm ob sab thiab sab saum toj ntawm lub vuam seam, thiab lub viav vias amplitude ntawm vuam pas nrig yuav tsum tsis txhob siab tshaj qhov dav ntawm vuam. seam.Kev ua haujlwm ntawm lub vuam pas nrig yog zoo ib yam li lwm cov ntsug vuam nrog grooves.

(4) Thaum vuam txheej txheej, qhov saum npoo ntawm cov vuam yog txiav txim siab los ntawm txoj kev thauj mus los.Crescent-shaped strips tuaj yeem siv rau vuam seam nto nrog ntau dua;zigzag strips tuaj yeem siv rau qhov chaw tiaj tus (cov duab concave hauv nruab nrab yog cuam tshuam nrog lub sijhawm ncua).

Mild steel electrodes haum rau ntsug vuam yogAWS E6013, AWS E6010, AWS E6011, AWS E7018, tshwj xeebE6011yog haum rau ntsug up-hauv qab vuam.

Daim duab 4. Tianqiao nyiaj siv ua haujlwm vuam

Overhead welding

Welding yam ntxwv ntawm overhead welding:

1. Cov hlau molten ntog vim lub ntiajteb txawj nqus, thiab cov duab thiab qhov loj ntawm lub pas dej molten yuav tsum tsis txhob tswj.

2. Nws yog ib qho nyuaj rau kev thauj cov sawb, thiab qhov chaw ntawm lub vuam tsis haum rau vuam.

3. Qhov tsis xws luag xws li slag inclusion, incomplete penetration, weld hlaws thiab tsis zoo weld tsim yog ib qho yooj yim mus tshwm.

4. Lub molten weld hlau splashes thiab kis tau, uas yuav yooj yim ua rau scalding xwm txheej.

5. Qhov ua tau zoo ntawm kev siv lub taub hau vuam yog qis dua li ntawm lwm txoj haujlwm.

Welding cov ntsiab lus ntawm overhead welding:

1. Kev siv lub taub hau ntawm lub taub qab welds.Thaum lub thickness ntawm lub vuam yog tsawg dua los yog sib npaug rau 4 hli, siv hom I grooves thiab siv φ3.2mm vuam rods nrog nruab nrab vuam tam sim no;Thaum lub vuam thickness ntau dua los yog sib npaug rau 5 hli, ntau txheej thiab ntau qhov vuam yuav tsum tau siv.

2. Lub vuam seam ntawm T-shaped sib koom ua ke yog nyiaj siv ua haujlwm vuam.Thaum vuam ko taw tsawg dua 8 hli, ib txheej vuam yuav tsum tau siv, thiab thaum vuam ko taw loj dua 8 hli, ntau txheej thiab ntau txheej vuam yuav tsum tau siv.

3. Raws li qhov xwm txheej tshwj xeeb, txais yuav txoj kev xa khoom kom raug:

(1) Thaum qhov loj ntawm qhov vuam ko taw me me, cov kab sib txuas lossis cov kab sib txuas yog siv los ua kom tiav ib txheej txheej vuam;Thaum qhov loj ntawm qhov vuam ko taw yog qhov loj, ntau txheej vuam los yog ntau txheej txheej ntau dhau vuam siv tau, thiab thawj txheej yuav tsum siv txoj kab ncaj nraim thauj mus los, lwm txheej txheej tuaj yeem xaiv oblique daim duab peb sab lossis oblique nplhaib thauj txoj kev.

(2) Txawm hais tias yuav siv txoj kev thauj mus los zoo li cas, cov hlau vuam yuav tsum tsis txhob ntau dhau txhua zaus nws hla mus rau lub pas dej molten.

Me me steel electrodes haum rau nyiaj siv ua haujlwm vuam yogAWS E6013, AWS E6010 AWS E6011, AWS E7018

Daim duab 5. Tianqiao kab rov tav vuam

Daim duab 5. Tianqiao kab rov tav vuam

Kab rov tav vuam

Vuam yam ntxwv ntawm kab rov tav welding:

1. Cov hlau molten tau yooj yim poob rau ntawm qhov zawj vim nws qhov hnyav, ua rau muaj qhov tsis xws luag nyob rau sab sauv, thiab teardrop-shaped weld hlaws lossis tsis tiav kev nkag mus rau sab qis.

2. Molten hlau thiab slag yog yooj yim cais, me ntsis zoo li ntsug vuam.

Cov ntsiab lus tseem ceeb ntawm kab rov tav vuam:

1. Cov pob qij txha kab rov tav vuam grooves feem ntau yog V-puab lossis K-puab, pob tw pob tw nrog lub phaj tuab ntawm 3 ~ 4 hli tuaj yeem welded ntawm ob sab nrog hom kuv grooves.

2. Siv txoj kab uas hla me me vuam pas nrig, qhov vuam tam sim no me dua li vuam vuam, luv luv arc ua haujlwm, tuaj yeem tswj tau qhov ntws ntawm cov hlau molten zoo dua.

3. Thaum welding tuab daim hlau, ntxiv rau hauv qab vuam, nws raug nquahu kom siv cov txheej txheem ntau txheej thiab ntau dhau welding.

4. Rau ntau txheej thiab ntau qhov kev sib txuas, yuav tsum tau them nyiaj tshwj xeeb rau kev tswj qhov sib tshooj ntawm qhov sib txuas ntawm qhov vuam.Rau txhua qhov sib tshooj welding, pib welding ntawm 1/3 ntawm cov welding yav dhau los los tiv thaiv qhov tsis sib xws.

5. Raws li qhov xwm txheej tshwj xeeb, tuav lub kaum sab xis vuam kom zoo, thiab qhov vuam ceev yuav tsum yog me ntsis blocky thiab zoo ib yam.

6. Siv txoj kev xa khoom kom raug.

(1) Rau Hom I pob tw kab rov tav welding, nws yog qhov zoo dua los siv cov txheej txheem reciprocating linear sawb rau pem hauv ntej vuam seam;ncaj los yog me me oblique ncig strips yuav tsum tau siv rau thicker qhov chaw, thiab ncaj strips nyob rau sab nraum qab, thiab vuam tam sim no yuav tsum tau nce kom tsim nyog.

(2) Siv lwm yam bevel pob tw kab rov tav vuam.Thaum qhov sib txawv me me, cov vuam hauv qab tuaj yeem siv cov kab ncaj nraim;Thaum qhov sib txawv loj, cov txheej hauv qab tau txais cov kab sib txuas reciprocating;thaum lwm cov khaubncaws sab nraud povtseg yog ntau txheej vuam, cov hlua inclined tuaj yeem siv tau.Kev thauj mus los ncaj nraim yuav tsum tau siv rau kev thauj mus los ntawm cov strips thiab ntau txheej thiab ntau qhov vuam.

Cov hlau me me electrodes haum rau kab rov tav vuam yogAWS E6013, AWS E6010, AWS E6011, AWS E7018

Post lub sij hawm: Lub Xya hli ntuj-21-2021